Section V - Integrated Dryer (option)

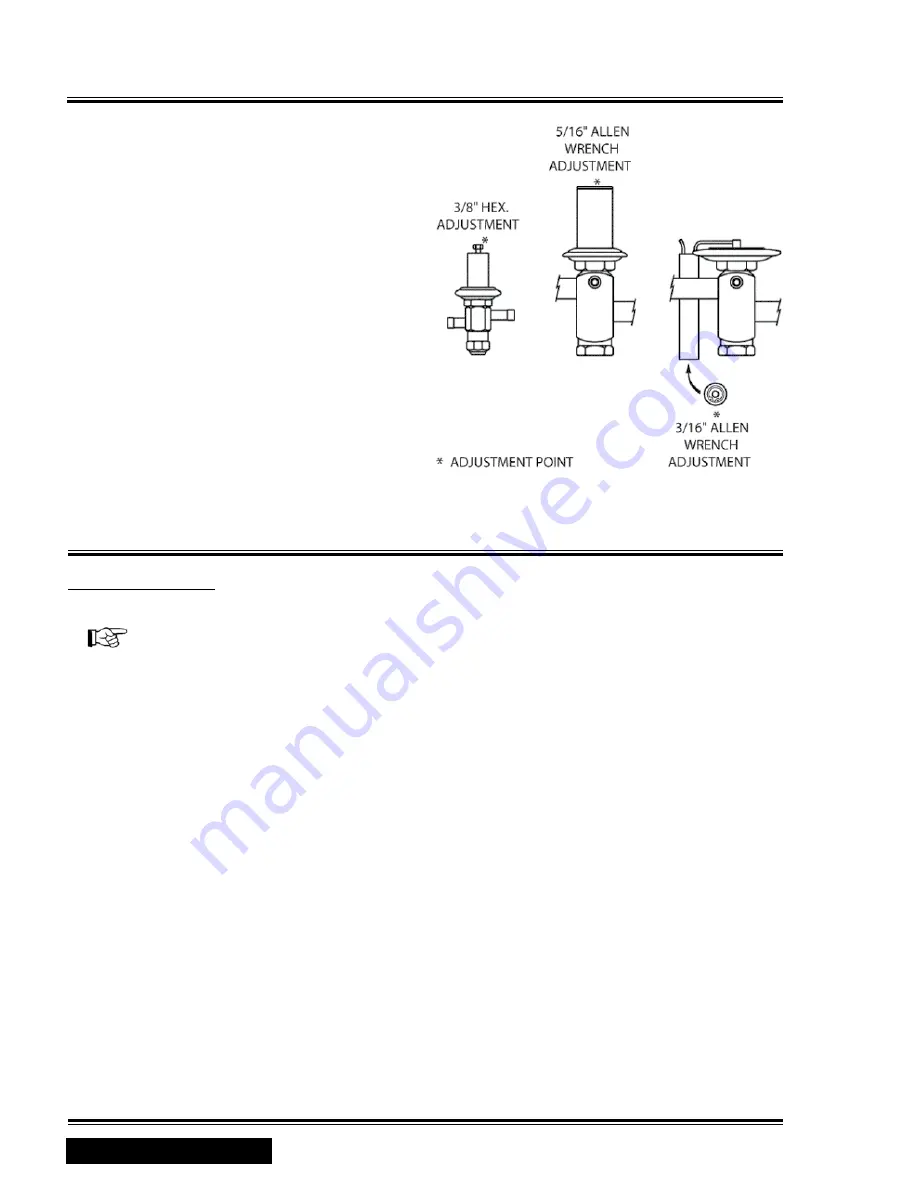

Hot Gas Bypass Valve

Integrated air dryers come equipped with

modulating hot gas bypass valves. This

valve maintains the refrigerant suction

pressure in varying load conditions.

The dryer will run from no load to full

load conditions without freeze-up. The

operation of this valve is automatic. If

the valve needs adjustment, turn the

adjusting stem clockwise to raise the

suction pressure, and counterclockwise to

lower the suction pressure. This adjustment

should be made under a no-load

condition. When the adjustment is made,

turn one quarter of a turn at a time, and

wait 3 to 5 minutes between adjustments.

Once the adjustment is complete, secure

the adjusting stem with the locknut that is

provided. Careful adjustment of this valve

is necessary for normal operation of the

air dryer. Hot gas bypass valve adjustment

may be made by maintenance personnel.

Hot Gas Bypass Valve Adjustments

Troubleshooting

notiCe!

The alarm indication light (red) signifies

the refrigerant compressor is not

running. The reasons can be:

•Low suction pressure

•High discharge pressure

•Electrical problems

•Loss of refrigerant

•Dirty condenser

•Leaking evaporator, etc.

Refer to the Troubleshooting section for

problem analysis and remedy. Call the

factory if further assistance is required.

The following conditions can cause

abnormal operation or malfunction of the

air dryer:

• High inlet air temperatures

• Dirty condenser

• Low ambient temperatures

• Malfunctioning automatic drains at

aftercooler, or dryer

• Refrigerant overcharge

• Leaky evaporator

• Electrical power supply more than

±10% of the rated voltage

• Low inlet air pressures

• High ambient temperatures

• Compressed air flow greater than rated

capacity

• Undersized fuses

• Refrigerant undercharge

If any of these symptoms are noticed, refer

to Section VIII - Troubleshooting.

30

Quincy Compressor-QGB

™

Back to Table of Contents