Section VI - Servicing

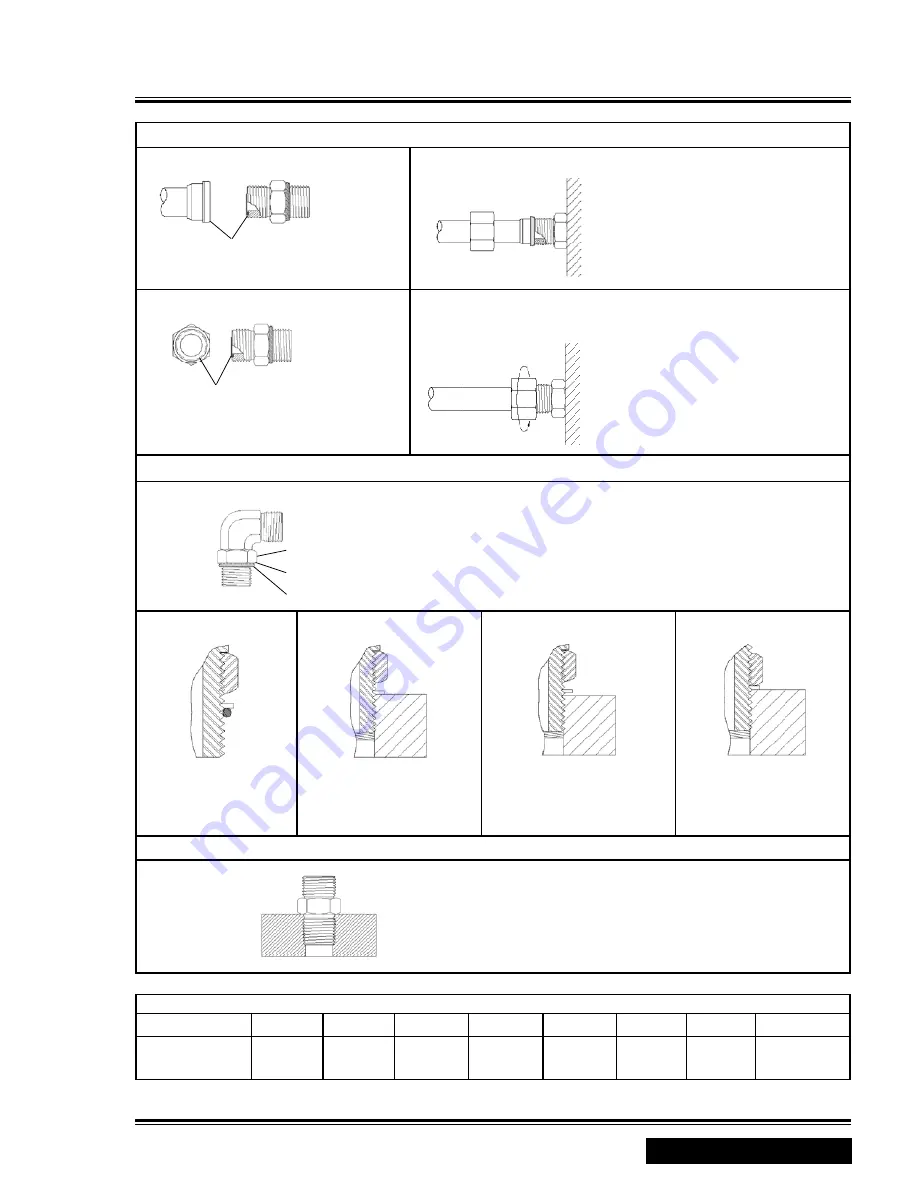

aSSeMBLing tHe FaCe SeaL enD

2) inStaLL o-ring

3) PoSition to Fitting

1) CHeCK SeaLing SurFaCeS

4) tHreaD on nut BY HanD &

5) WrenCH tigHten

aSSeMBLing aDJuStaBLe enD to Port

CORRECTLY SIZED O-RING

IS 0.070” THICK AND ITS O.

D. TOUCHES THE OUTSIDE

EDGE OF THE GROOVE.

aSSeMBLing non-aDJuStaBLe Port enD

CHECK SEALING SURFACE

AND GROOVE FOR DAMAGE

OR MATERIAL BUILDUP.

IF PROPERLY ALIGNED, THE NUT

SHOULD THREAD ON EASILY BY HAND.

WRENCH TIGHTEN TO RECOMMENDED

TORQUE FOR FACE SEAL END.

ENSURE THAT O-RING IS PROPERLY

SEATED IN THE GROOVE.

POSITION AND HOLD FLAT SEALING

FACE AGAINST O-RING.

2) BaCK oFF nut

BACK OFF LOCKNUT

TO ITS UPPERMOST

POSITION

3) tHreaD into Port

THREAD FITTING INTO

THE PORT UNTIL THE

BACKUP WASHER CON-

TACTS THE SURFACE

4) BaCK oFF For aLignMent

POSITION FITTING FOR

ATTACHING LINE BY UN-

THREADING UP TO 360°

5) WrenCH tigHten

WRENCH TIGHTEN

LOCKNUT

1) CHeCK SeaLing SurFaCeS & inStaLL o-ring

• INSPECT FITTING FOR DAMAGE

• USE O-RING INSTALLATION TOOL TO INSTALL O-RING

• APPLY SMALL AMOUNT OF LUBRICANT TO O-RING

LOCKNUT

BACKUP WASHER

O-RING

• INSPECT SEALING SURFACES FOR DAMAGE

• INSTALL O-RING

• THREAD FITTING INTO PORT AND WRENCH TIGHTEN

SEAL-LOK ASSEMBLY TORQUES (IN LBS)

DASH SIZE

4

6

8

10

12

16

20

24

FACE SEAL

220

320

480

750

1080

1440

1680

1980

END

(+/-) 10

(+/-) 25 (+/-) 25

(+/-) 35

(+/-) 45 (+/-) 90 (+/-) 90 (+/-) 100

Quincy Compressor-QGB

™

5

Back to Table of Contents