Section V - Integrated Dryer (option)

Maintenance

The dryer is factory tested before shipping.

All controls are calibrated for automatic

operation. If the dryer is installed in clean

surroundings, within the temperature limits

of the specified ambient, the dryer will run

trouble-free for a very long time. Routine

maintenance procedures recommended

are the following:

1) Check the fan motor(s) for proper

operation to maintain the cooling air

to be drawn through the condenser

and blown over the refrigerant

compressor.

2) Clean the condenser periodically to

maintain the proper heat transfer on

the condenser coil. Dirty condenser

will raise the head pressure of the

refrigeration system and trip the

compressor “off” at the overload

control. Running the compressor

on high head pressures may cause

premature failures. Check the

ambient temperature limits to be

maintained at the installation.

3) Pressure drop across the dryer may

increase slowly as the particulate

material coming through the air

stream plugs up the internals of

the heat exchanger. A back-flush

procedure is recommended to clean

the air system.

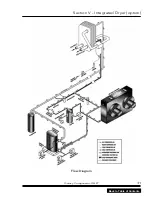

To back-flush, disconnect air dryer, plug

the drain line and fill the air system with

the detergent water solution. Hold it for

4-6 hours. Circulate the detergent from air

outlet to air inlet with a pump. Flush the

system with warm water. If pressure-drop

still exists, contact factory.

Back-flush Flow Diagram

Quincy Compressor-QGB

™

27

Back to Table of Contents