1

QMB/T

®

Control Operations

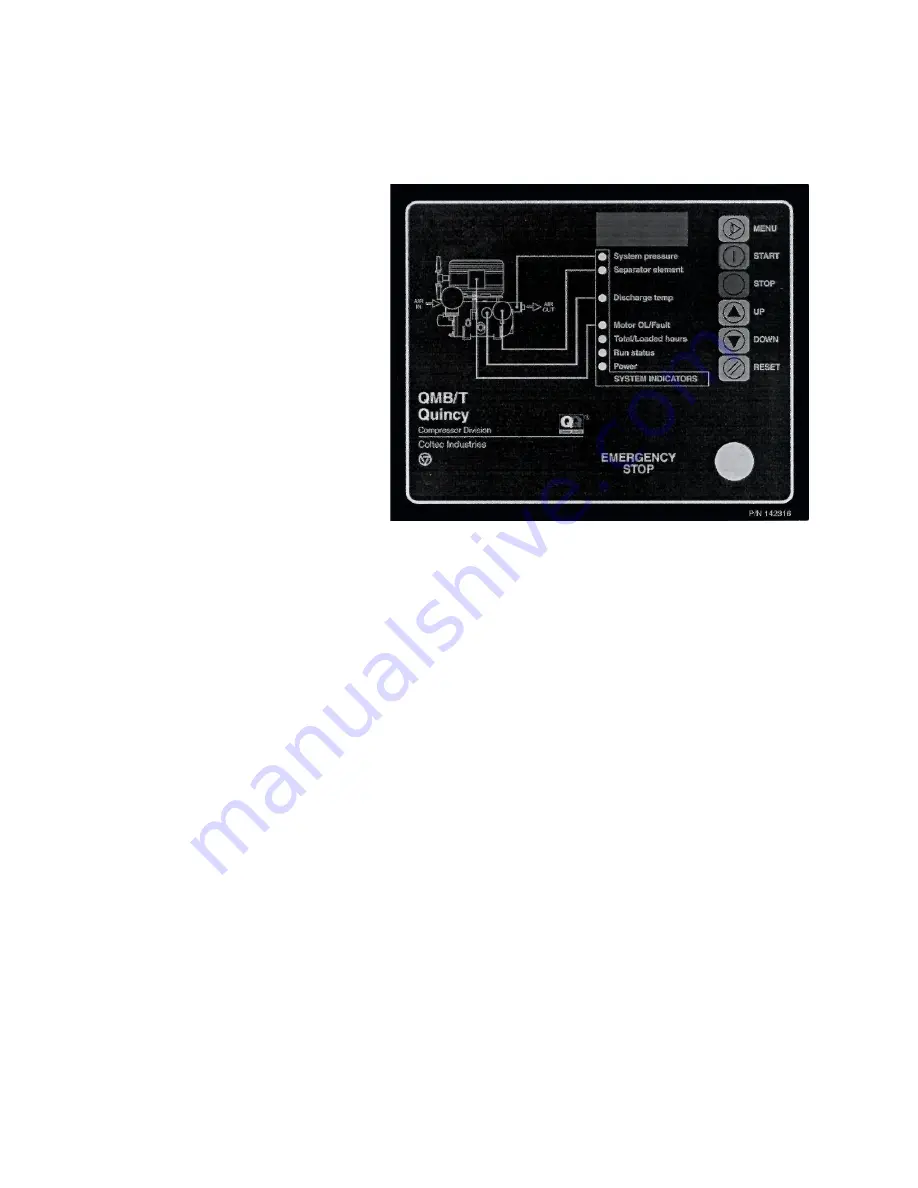

This manual describes the microprocessor control for the QMB/T series of Air Compressors.

The decal at the right shows the control

layout for the electronic control panel.

The primary controls are on the right

hand side of the panel, with the selected

item being displayed on the LED digits

in the top window.

The LED lamps in a vertical column,

show the selected display parameter

and/or any alarm conditions.

On applying system power the LED

status lights will blink and the numeric

display will show the version number of

the software code installed. The system

will be ready to run with the 'POWER'

lamp on (showing that the control board

has power) and the 'SYSTEM PRESSURE' LED will be lit showing the pressure on the numeric display.

NOTE: A flashing '----' on the digit display, accompanied with an LED on the left, signifies a faulty

sensor, either the pressure transducer or the temperature probe.

A

FAST

blinking LED indicates that the labeled function has been tripped; an over-pressure condition or

motor overload or High Air Temperature (HAT) trip.

A

SLOW

blinking LED indicates that the Separator Differential Pressure (D.P.) switch has been tripped.

A

STEADY

LED, along with a message blinking on the display, indicates a service time-out. The

controller is programmed with recommended service intervals on the fluid filter and the air filter. These

filters should be checked and serviced when convenient.

Summary of Contents for QMB Series

Page 2: ......

Page 9: ...7 WIRING DIAGRAM ACROSS THE LINE STARTING ...

Page 10: ...8 WIRING DIAGRAM WYE DELTASTARTING ...

Page 11: ......