8

START-UP AND OPERATION

PRELIMINARY CONTROLS

Before starting the dryer, check for:

1.

The correct connection to the compressed air piping:

remember to remove end caps on the dryer inlet and

outlet.

2.

The correct connection to the condensate drainage

system.

3.

The correct power supply.

STARTING AND STOPPING

Always start the dryer at least 5 minutes before the air

compressor starts running and stop it after the air

compressor has been stopped in order to keep the

compressed air piping free of condensate. The dryer must

be kept running while the air compressor is running.

PRESSURE DISCHARGE PROCEDURE

See Figure 13 on Page 10.

1.

Isolate the dryer from the air system (1).

2.

Release the pressure in the dryer by pressing the

condensate drain “TEST” pushbutton located on the

auto drain (2).

3.

Switch off the machine by turning the STOP button to

position “0 OFF” (3).

4.

Turn off the power supply by opening the circuit

breaker or fused disconnect switch (4).

CALIBRATIONS

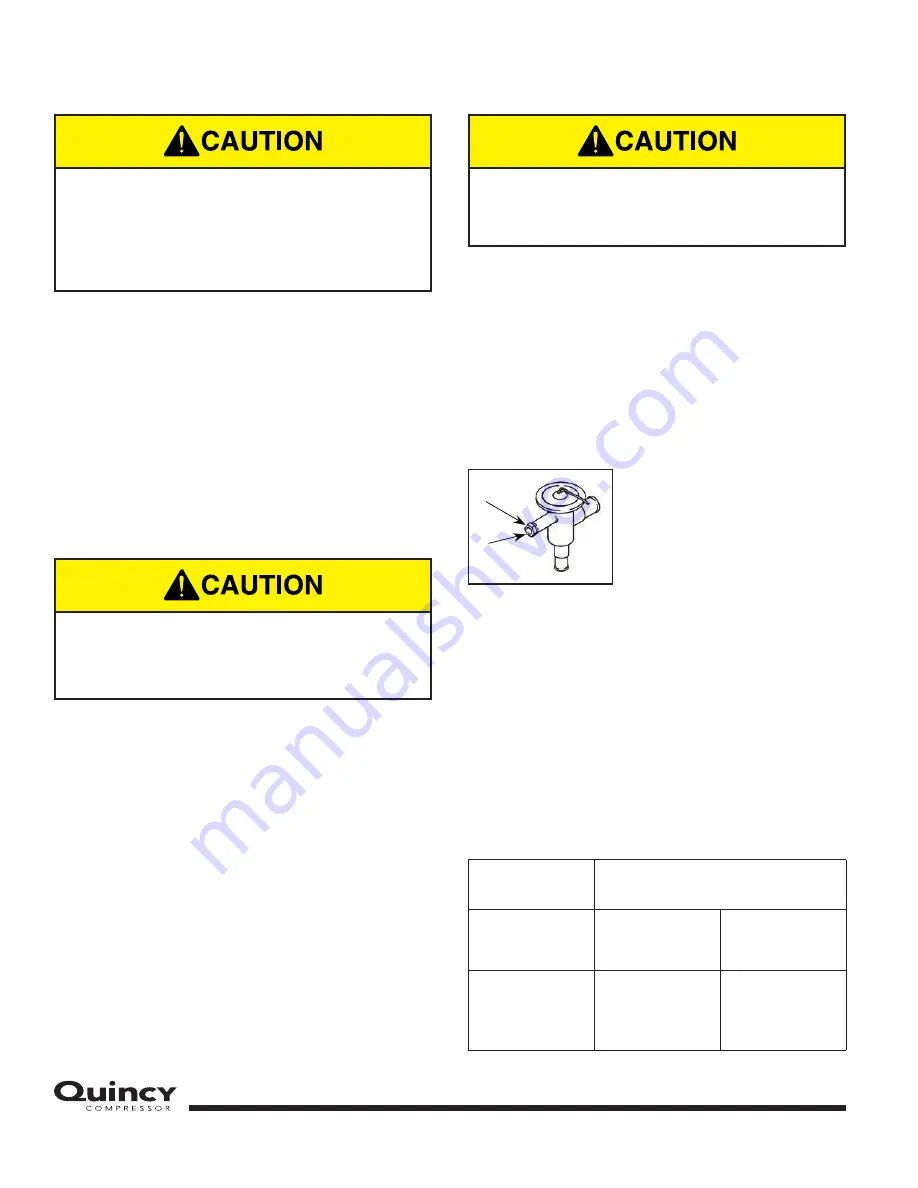

HOT GAS BYPASS VALVE

These valves have already been calibrated and they do

not require any adjustment. A dew point different from the

rated one generally is caused by factors which are not

attributable to their operation. Figure 10 shows:

1.

Closing cap

2.

Adjusting screw

This valve maintains the

refrigerant suction pressure in

varying load conditions. The

dryer will run from no load to

full load conditions without

freeze-up. The operation of this

valve is automatic. If the valve

needs adjustment, turn the

adjusting stem clockwise to

raise the suction pressure, and

counterclockwise to lower the suction pressure. This

adjustment should be made under a no-load condition if

possible. When the adjustment is made, turn one quarter

of a turn at a time, and wait 3 to 5 minutes between

adjustments. Careful adjustment of this valve is necessary

for normal operation of the air dryer. Hot gas bypass

valve adjustment may be made by maintenance

personnel. (See Figure 10.)

Table 2 — WORKING PRESSURES AND

TEMPERATURES OF R404A

Before making any change to the machine,

ensure that the electric power supply has

been disconnected. Wait at least two hours

before starting up after any machine

movement (transport or handling).

The following procedure must be per-

formed by skilled personnel approved by

the manufacturer.

If the dryer is switched off, before starting

it again, wait at least 5 minutes to allow

for pressure balancing.

SUCTION SIDE OF

REFRIGERATION COMPRESSOR

Evaporating

Temperature

°F (°C)

Evaporating

Pressure

psi (bar)

RATED VALUES

AT AMBIENT

TEMPERATURE

+68 °F (+20 °C)

33.8 - 35.6

(1 - 2)

R404A

74 - 76

(4.3 - 4.5)

2

1

FIGURE 10 —

BYPASS VALVE

Summary of Contents for QPNC 100

Page 16: ...14 QPNC 75 External Parts List...

Page 18: ...16 QPNC 75 Internal Parts List...

Page 20: ...18 QPNC 100 125 External Parts List...

Page 22: ...20 QPNC 100 125 Internal Parts List...

Page 24: ...22 QPNC 150 200 250 External Parts List...

Page 26: ...24 QPNC 150 200 250 Internal Parts List...

Page 28: ...26 QPNC 75 Dimensional Drawing...

Page 29: ...27 QPNC 100 125 Dimensional Drawing...

Page 30: ...28 QPNC 150 to 250 Dimensional Drawing...

Page 31: ...29 QPNC 75 115V Wiring Diagram...

Page 32: ...30 QPNC 75 230V Wiring Diagram...

Page 33: ...31 QPNC 100 125 115V Wiring Diagram...

Page 34: ...32 QPNC 100 125 230V Wiring Diagram...

Page 35: ...33 QPNC 150 175 200 250 Wiring Diagram...

Page 36: ......

Page 37: ......