5

INSTALLATION INSTRUCTIONS

LOCATING THE DRYER

FLOOR

The floor must be even and of industrial type; the total

weight of the machine is shown in Figure 4.

Consider the total weight of the machine when positioning it.

Consider the total weight of the machine when positioning it.

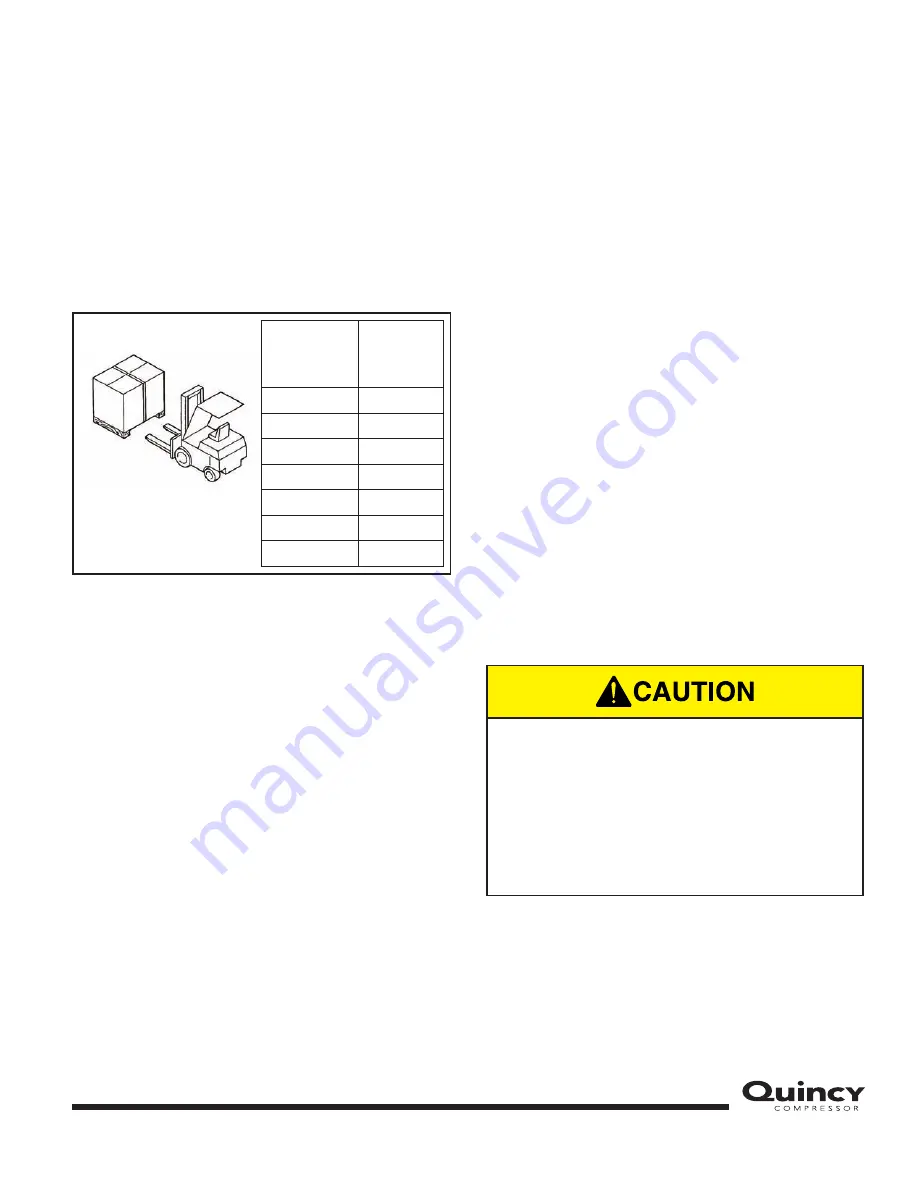

FIGURE 4 — MODEL WEIGHT

VENTILATION

The choice of an appropriate room will prolong the life of

your dryer. The room must be spacious, dry, well-

ventilated and free from dust.

DESIGN CONDITIONS

Min. room temperature:

+ 40 °F (+ 4.5 °C)

Max. room temperature:

+ 115 °F (+ 46 °C)

Min. temperature of incoming air:

+ 40 °F (+ 4.5 °C)

Max. temperature of incoming air:

+ 131 °F (+ 55 °C)

Max. working pressure:

203 psi (14 bar)

TRANSPORT AND HANDLING

The machine must be transported as shown in Figure 4.

POSITIONING

After unpacking the equipment, preparing the dryer’s

room, and putting the machine into position, check the

following items:

1.

Ensure that there is sufficient space around the

machine to allow maintenance (see Fig. 5).

2.

Ensure that the operator can see the whole machine

from the control panel and can check for the

presence of unauthorized persons in the machine’s

vicinity.

ELECTRICAL CONNECTION

1.

Check that the supply voltage is the same as the

value indicated on the machine’s identification plate.

2.

Check the condition of the line leads and ensure that

there is an efficient earth ground lead.

3.

Dryer must be wired to the power supply through a

fused disconnect switch or circuit breaker in

accordance with national and local electrical codes

to protect against overcurrents, with ground-fault

circuit interrupter protection, if required by local

codes (see Figure 5).

NOTE:

There is a copy of the wiring diagram inside the

electric panel.

Model

Gross

Weight

lb. (kg.)

QPNC 75

112.4 (51)

QPNC 100

134.5 (61)

QPNC 125

149.9 (68)

QPNC 150

198.4 (90)

QPNC 175

198.4 (90)

QPNC 200

198.4 (90)

QPNC 250

198.4 (90)

Only professionally skilled personnel may

have access to the electrical panel. Switch

off the power supply before opening the

door to the electrical panel. Compliance

with national and local codes concerning

electrical plants is fundamental for operator

safety and for the protection of the

machine.

Summary of Contents for QPNC 100

Page 16: ...14 QPNC 75 External Parts List...

Page 18: ...16 QPNC 75 Internal Parts List...

Page 20: ...18 QPNC 100 125 External Parts List...

Page 22: ...20 QPNC 100 125 Internal Parts List...

Page 24: ...22 QPNC 150 200 250 External Parts List...

Page 26: ...24 QPNC 150 200 250 Internal Parts List...

Page 28: ...26 QPNC 75 Dimensional Drawing...

Page 29: ...27 QPNC 100 125 Dimensional Drawing...

Page 30: ...28 QPNC 150 to 250 Dimensional Drawing...

Page 31: ...29 QPNC 75 115V Wiring Diagram...

Page 32: ...30 QPNC 75 230V Wiring Diagram...

Page 33: ...31 QPNC 100 125 115V Wiring Diagram...

Page 34: ...32 QPNC 100 125 230V Wiring Diagram...

Page 35: ...33 QPNC 150 175 200 250 Wiring Diagram...

Page 36: ......

Page 37: ......