Pre-operation(continued)

Package Contents & Assembly

Package contents:

■ Air Compressor

■ Ownefs Manual

■ AirFilter

Assembly:

■ Attach the air filter and screw it in properly.

Inspect for Damage

Before using the Air Compressor, make sure the air tank is not

damaged, inspect all parts for damage, and check that all pipes

are firmly connected.

Do not use the Air Compressor tt any damage is found. If

damaged, have an authorized service center inspect and test the

Air Compressor to ensure that is working properly.

Save Packaging

Save all outside packaging in case you ever need to return the

product for service or repair.

Compressor Location

Use on Flat Surface

For proper operation, the Air Compressor must be placed on a flat

surface

with

an incline no greater than 15 degrees.

A.WARNING

EXPLOSION

FIRE

Use caution to minimize risk of fire or explosion.

It is normal for the Air Compressor motor and

pressure switch to produce sparks while operating. If

sparks come in contact with vapors from gasoline or

solvents, they may ignite and cause a fire or

explosion.

Abrasive tools such as grinders, drills and other

tools are capable of making sparks that can ignite

flammable materials.

Always operate the Air Compressor at a sale distance

away

from flammable items. Use in well-ventilated

areas.

Never exceed the maximum rated pressure.

8

Maintain a Clear Area

It is very important that the Air Compressor is positioned so that

there is adequate airflow around the machine. There must be at

least 2 ft. of obstacle-free space surrounding and above the Air

Compressor.

A.WARNING

RISK TO BREATHING

Dust or dust-like particulates caused by

power-sanding, sawing, grinding, drilling or any

other construction-like activities can contain

contaminants that are harmful to breathe.

Always use your Air Compressor

in

a well-ventilated

and clean area.

Never breathe the air that comes directly out of the

Air Compressor or air hose. This air Is not suitable for

breathing.

Always wear approved safety equipment. When

performing dust-creating activities, securely wear

properly-fit lace masks or respirators.

II

you feel

ill

from breathing while operating your Air

Compressor, stop and seek medical attention

immediately.

Use in Areas with Clean Air

For proper operation and to maximize the longevity of the Air

Compressor, it is very important that the air drawn into the Air

Compressor is clean. The Air Compressor should not

be

used in

areas where dust or particulates are in the air. This will damage

the motor and impair proper operation.

IMPORTANT:

Always use the air filter, properly installed.

Summary of Contents for 10-2-SIL

Page 1: ...COMPRESSOR ...

Page 2: ......

Page 4: ...dust ...

Page 6: ...ft ...

Page 7: ...1 68 ...

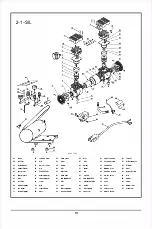

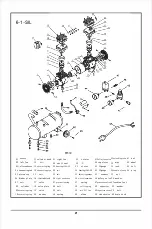

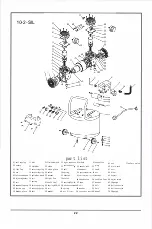

Page 11: ...TOOL USAGE Model 2 1 SIL 2 1 SIL AL 6 1 SIL ...

Page 18: ...CARE CLEANING ...

Page 21: ...2 1 SIL AL 20 ...

Page 24: ......