MOUNTED MACHINE:

1.

Make sure that the lifting system is working smoothly before coupling the machine

on the tractor linkage.

2.

Make sure the linkage category of the machine is the same as that of the tractor.

3.

Be careful when standing near the linkage system area. There are risks of crushing

and cutting.

4.

Do not stand between the machine and the tractor during the coupling and when

you fit the top link.

5.

Adjust the check chains of the linkage of the tractor to avoid excessive sway.

6.

In transport lock the operating lever of the linkage.

7.

Set the lighting apparatus, signal system and required precautions for transport on

the road.

8.

Put on the safety pin and release the locking system in transport position.

9.

Check the following regularly: axles, lynch pins, articulation pins, linkage bar.

SEMI MOUNTED & TRAILED MACHINES:

1.

Make sure that the drawbar, turning link, fix link and hook is in good working order.

2.

Check the connection to the tractor: linkage pins, hook, axles, pins etc.

3.

Do not stand between the tractor and the machine at the time of coupling.

4.

Never attach a trailed machine to the top link hitch point of the tractor

-SERIOUS RISK OF OVERTURNING

5.

Regularly check and clean the hydraulic pipe connection, rams safety valves on the

road

etc.

6.

In transport put on the safety pins and release the locking system.

7.

In transport close the safety valves of the lifting rams of the machine.

8. When

transporting

drive

carefully on the road especially on sharp curves and on

bridges etc.

9.

Set up lights, signal systems and transport locks for road transportation.

10. Do not uncouple the machine when on sloping ground. If necessary place a

securing block behind the wheel.

11. Before leaving the tractor uncouple the machine. Lay the machine on the ground or

on the support stand.

12. Open and close on a flat area with the tractor running at low revs.

MACHINE WITH HYDRAULIC EQUIPMENT:

1.

Check the hydraulic kit, pipes, connections and valves are all in smooth working

order before use.

2.

Read the setting up procedure before use as shown herewith.

3.

Before use fill up the hydraulic circuit by moving the spool valve of the tractor.

4.

Keep people away from the driving area and be careful with large unfolding

machines.

5.

IMPORTANT - In transport close the safety valves of the rams.

6.

On vertical and lateral folding machines put all release pins on.

7.

Do not attempt to execute more than one operation at a time. Wait for one to finish

before starting another.

8.

Carry out all the operations on a flat surface with the tractor running at low revs.

Leave the machine on a flat area.

Summary of Contents for SCD

Page 2: ...MACHINE DETAILS Model Serial Number Date Of Manufacture...

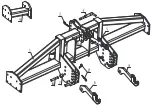

Page 7: ......

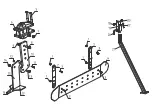

Page 8: ......

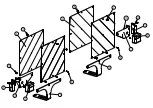

Page 10: ......

Page 12: ......