PTO SHAFT:

1.

Use the PTO shaft recommended by the manufacturer, which has a CE Mark.

2.

Keep the guards and covers on the PTO Shaft.

3.

At all times be careful with the PTO Shaft.

4.

Never attach the PTO when the machine is lifted.

5.

Lift the PTO Shaft to check that the guards move freely and cover the shaft.

6.

IMPORTANT - Secure the chains of the PTO Shaft to ensure protection.

7.

Before connecting the PTO Shaft make sure the RPM is the same as the machine.

8.

When engaging the PTO Shaft ensure that no person is standing near the machine.

9.

Never engage the PTO when the engine is a stopped or running at high rev.

10. Ensure that no person stands near the moving parts of the machine.

11. Do not allow hands, feet or any other part of the body near the moving parts of the

machine.

12

Disengage the PTO Shaft if the work becomes too much for the machine -

DO NOT OVERSTRAIN THE PTO.

13. Do not stand near the working machine even if the tractor PTO is disengaged

WAIT FOR ALL MOVING PARTS TO STOP.

14. Carry out maintenance, greasing, cleaning and all other necessary work when the

PTO Shaft is disconnected, the engine is stopped, the key away and the machine is

stabilized.

15. Position the disconnected PTO Shaft on supports in order to avoid damage when in

transport.

16. IMPORTANT - Always replace a broken or defective part by an original part, which

has a CE Mark.

MAINTENANCE:

1.

Carry out all maintenance, greasing, cleaning and any other work on the machine

ONLY when the machine is stopped, stabilized, engine stopped, handbrake on and

key out.

2.

Regularly check the bolts, linkage, link pin, articulation axles, wearing parts often.

Tighten them regularly and if necessary replace them with original parts.

3.

For all work that needs to be carried out under the machine make sure the unit is

wedged and supported carefully to avoid the risk of crushing. Take care with all

parts that could fall or uncouple from the machine when this maintenance is being

carried out.

4.

Wear gloves for all work that needs to be carried out on the machine. Be careful on

sharp edges.

5.

Before undertaking greasing clean carefully the surplus grease and oil.

6.

Before all welding operations on the machine when it is coupled with the tractor

disconnect the cables of the battery.

7.

Always replace the wearing parts or damaged parts with original ones.

Summary of Contents for SCD

Page 2: ...MACHINE DETAILS Model Serial Number Date Of Manufacture...

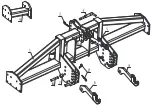

Page 7: ......

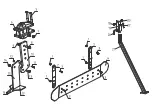

Page 8: ......

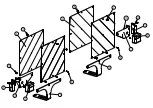

Page 10: ......

Page 12: ......