Q150T Sample Preparation System

10473 - Issue 5

26

Q150T - Instruction Manual

4.3.1

Creating a New Material

To create a new material:

1.

Select

Edit | Materials

from the menu bar.

Material Editor

is displayed (see

Figure 4-5

).

2.

Tap on

Materials

at the root of the material ‘tree’.

3.

Tap on the

New

button. The

New Material

dialog box is displayed.

4.

Enter a name for the profile: tap in the

Name

field to display the on-screen

keyboard (Figure 4-6) in the

Enter Name

dialog box.

5.

Tap on the

OK

button to confirm the changes to the material. Alternatively, tap on

the

Cancel

button to close the dialog box without creating a new material.

6.

The new material is created using the default settings for the chosen process type.

7.

Now refer to the

Editing Material Parameters

section.

4.3.2

Editing Material Parameters

Each material is defined by the parameters shown in Table 4:

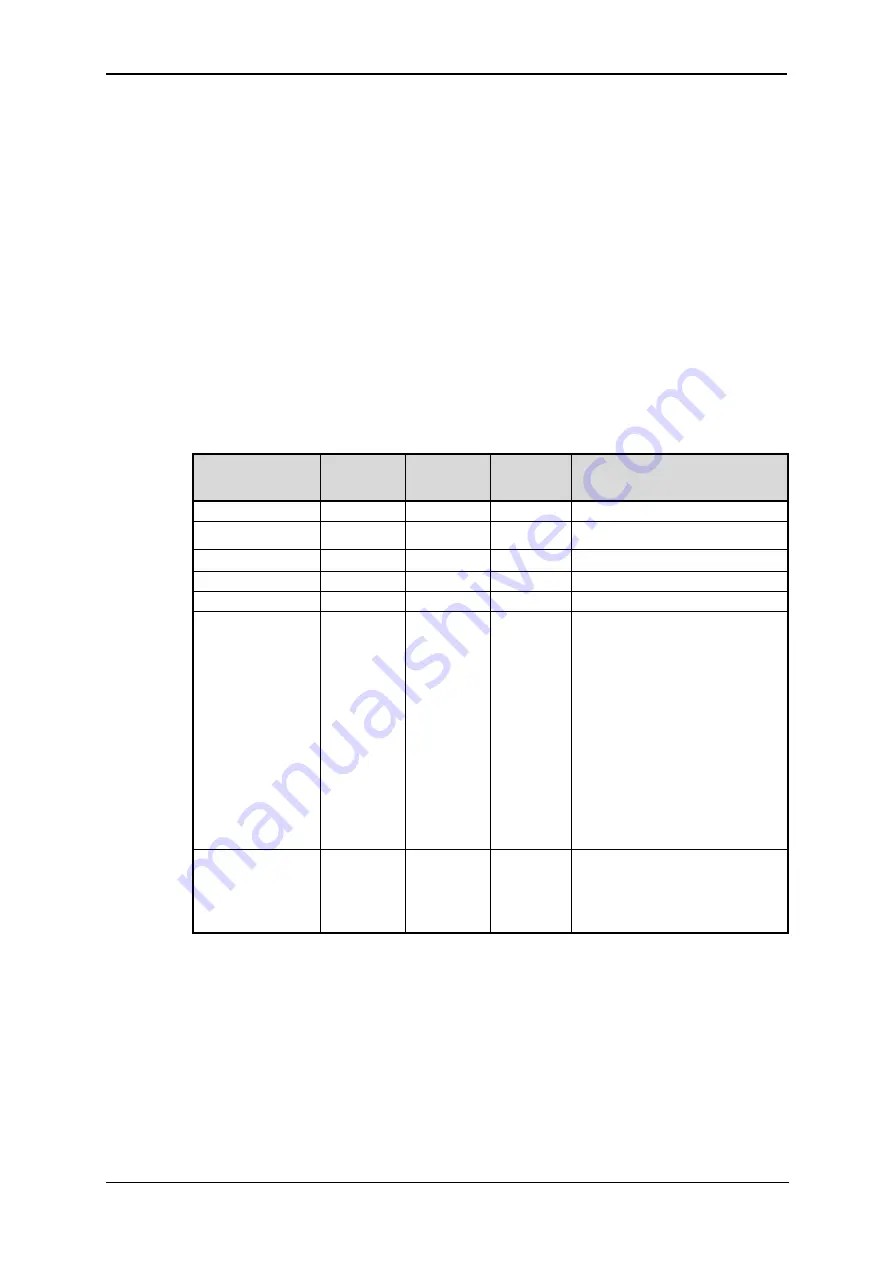

Table 4

Material parameters

Name

Default

Value

Minimum

Value

Maximum

Value

Comment

Density

10

1

30

Material Type

oxidising

noble

oxidising

Sputter Current

50

1

150

Clean Current

150

100

150

Material Tool

0.1

10

Sputter cleaning

mode*

Timed

Specifies how the material will be

cleaned. Options are:

Timed

Continuous sputter for fix time.

Pulse above

Cycle plasma until target voltage

is above that specified in

Sputter stop cleaning at

Pulse below

Cycle plasma until target voltage

is below that specified in

Sputter stop cleaning at

Only used during pulse cleaning

of target.

Sputter stop

cleaning at (Volts)*

250

90

600

Target voltage that needs to be

achieved before cleaning is

completed and the coating starts.

Only used during pulse cleaning

of target.

* Displayed for information only. Changes if required will need to be carried out by a Quorum

agent.

Summary of Contents for Q150T S

Page 92: ......