7. FAN OPERATION AND CARE

8. TROUBLESHOOTING

6. COMPLETING

THE

INSTALLATION

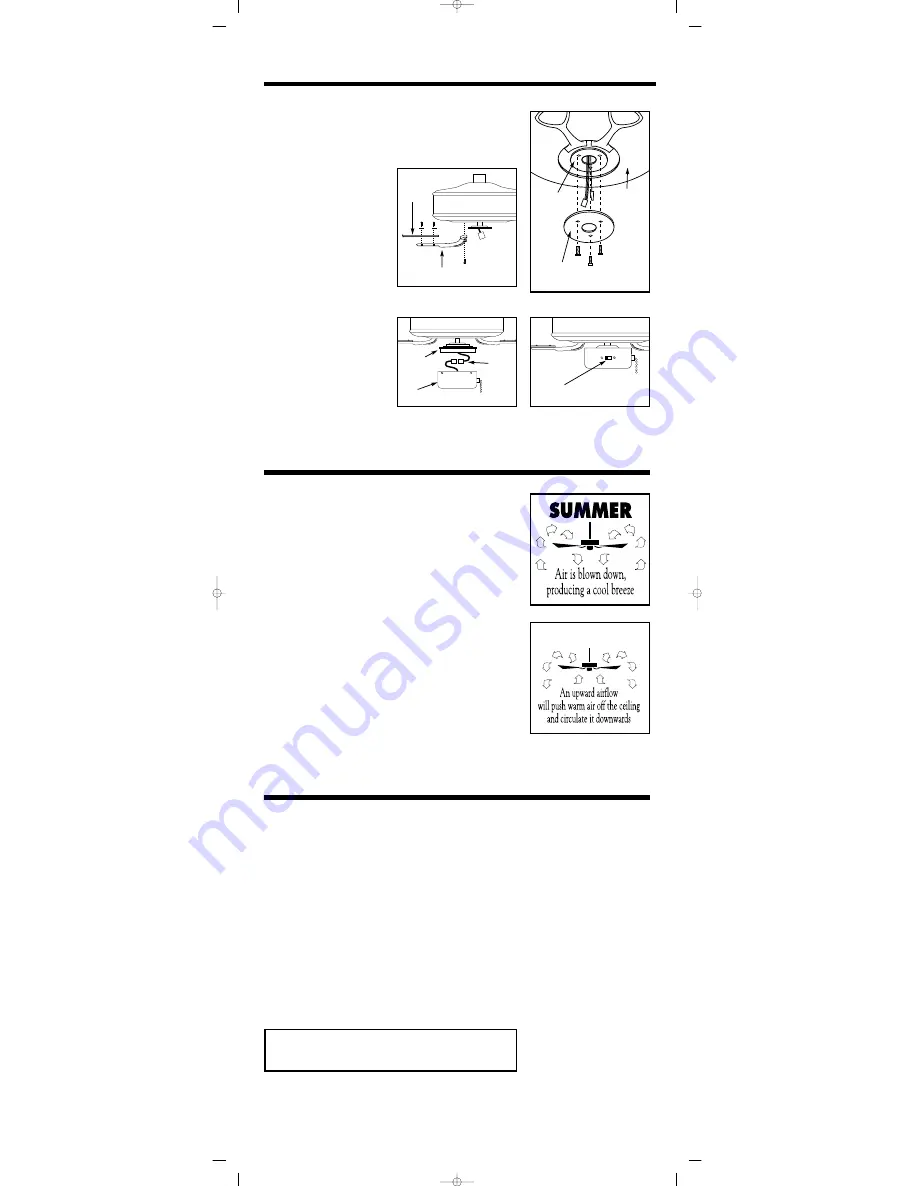

Fig. 14

WINTER

Fig. 15

1.

Make sure the wiring is safely inside

the outlet box as instructed in Step 5 -

Electrical Connections. To install the

canopy, partially unscrew the 2 screws in

the hanger bracket. Align the slotted

holes in the canopy with the screws in

hanger bracket. Push up the canopy so

the screws slip into the slot. Turn the

canopy so it locks in place. Make sure the

canopy is not quite touching the ceiling.

Blade Assembly & Installation

2.

(Fig. 10) Using the supplied blade

arm screws, attach the blades to the

blade arms. In some cases the metal

washer is permanently fixed to the screw

head. Ensure all screws are used for each

blade. Next attach the blades to the

motor assembly using the supplied

screws.

DO NOT bend the blade arms

when installing the blades.

Attaching the Control Cup

3.

(Fig. 11) Attach the control cup

plate to the flange of the motor by using

the three (3) screws provided that are

pre-installed on the flange. (Fig. 12) Join

the two ends of the square cannon plugs

(lining up the colors) and attach the con-

trol cup to the control cup plate with the

three (3) screws provided.

A certain amount of wobble may be

considered normal, especially if the fan

is on a downrod longer than 12".

4.

Turn on the fan and check the 4

position speed switch - 3 speeds and

stop. (Fig. 13) Check the reverse switch

NOTE: Wait for the fan to stop rotating

before changing from forward to reverse.

Fig. 12

Flange

Control Cup

Fig. 10

Blade

Blade Arm

1.

A ceiling fan is an environmentally

smart choice to cool as well as help to

warm your home or office. Adjust your

HVAC thermostat during fan use to save

additional energy and money on your air

conditioning and heating utility bills.

You should see a significant reduction in

both heating and cooling costs by regular

use of your fan.

Do not hesitate to use your fan dur-

ing summer and winter months. In sum-

mer, using the reverse switch, adjust the

fan’s direction so cool air is blown down,

producing a cooling breeze. (Fig, 14) In

winter, reverse the fan so that an upward

airflow will push warm air off the ceiling

and circulate it down into the living area

(Fig. 15). In winter months, use the fan

at a lower speed than summer.

2.

Periodically check tightness of all

screws securing the blades to the blade

arm attachment points. A clicking or

rattling noise is a sure indication of

loosening screws. Since screws will

invariably work loose over time, at least

once a year, tighten all the screws attach-

ing blades to blade arms.

Do not bend

blade arms when cleaning or servicing

the fan.

3.

Clean your fan periodically using

only a cloth dampened with a mild deter-

gent solution for all hardware - never use

solvents. The finish plating is lacquered

to prevent tarnishing. Use a lint-free cloth

with clean water to clean blades.

4.

You will never need to oil or lubri-

cate your fan. Its permanently sealed

bearings will provide trouble-free, silent

operation for many years.

5.

If repairs or servicing are ever

required, to avoid possible electric

shock,

turn off the electricity

at the

main fuse or circuit panel before you

begin.

FAN WILL NOT START

1.

Check that the electricity has been

turned on at the circuit breaker which

had probably been turned off during

installation.

2.

Turn off the electricity. Check all con-

nections in the wiring of the fan at the ceil-

ing and make sure it follows the wiring

instructions outlined in this manual.

NOISE

Note:

Always allow a day or two “run-in”

time for any new fan at medium or high

speed. When attempting to diagnose

noise, listen carefully from several sides

to try and isolate the location of the noise

(blades, upper end, motor, light kit, etc.).

1.

Tighten all screws attaching blades to

blade arms. Remember to tighten these

screws at least once a year because they

may loosen slowly over time and cause a

clicking noise.

2.

Turn off the power. Loosen the

canopy and check that the wiring and/or

wire nut connectors are not resting against

the canopy, possibly vibrating while the

fan is on.

3.

Use of a standard light rheostat or an

unapproved fan wall control to control the

fan speed will always cause an annoying

“hum”. Many fan motors do not work

quietly with solid state variable speed

controls.

4.

Check that the rubber gasket on the

mounting bracket has been installed if

called for in the installation instructions.

5.

Check that the canopy is not touching

the ceiling.

6.

Check that all screws on the motor

housing and the bottom housing are tight.

FAN TURNS, BUT DOES NOT

MOVE MUCH AIR

1.

The fan may be running in reverse.

2.

The distance from the ceiling to the

blades may be too small. For downrod

fans, optimal placement would be 8-9 feet

from the floor.

3.

The room may contain items which

obstruct the air flow.

4.

The fan may be too small for the size

of the room.

EXCESSIVE WOBBLE

Note: A small amount of wobble is con-

sidered acceptable and should not be con-

sidered a defect.

1.

Make certain all blades are tightly

attached to each blades' respective blade

arm.

REPLACEMENT PARTS AVAILABLE

A full range of genuine replacement spare parts are available at reasonable cost directly from

Quorum International. Please call us at (817) 626-5483, Monday through Friday from 8:00 A.M.

to 5:00 P.M. CST.

Fig. 13

Fig. 11

Reverse Switch

Cannon

Plug

Control Cup Plate

Flange

Fan

Estate Inst -5/04 WET 6/2/2004 11:22 AM Page 4

All manuals and user guides at all-guides.com