®

R&M Materials Handling, Inc

STAGEMAKER

®

COMPACT Concert Hoist

Springfield, Ohio USA

SM10 Installation & Maintenance Manual

: 800 955-9967

web:

www.rmhoist.com

June 2006

5 June 2006 32 SM10-M & I MANUAL - 2006 - 0.doc.

6.3

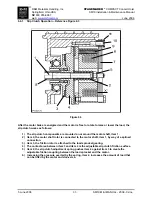

Motor / Body

The hoist motors are designed to provide dependable hoisting service. The standard motors and control

enclosures are enclosed for IP55 rated protection (NEMA 3R type) against normal hazards of dust and

moisture. The motor bearings are sealed and do not require further greasing.

The hoist body is coated with epoxy paint and constructed of aluminum. Remove from service and

replace the hoist body if damaged.

6.4

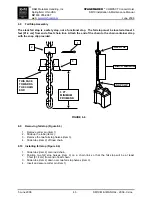

Hoist Motor Brake and Load-Limiting Device

The hoist is equipped with a D.C. electromagnetic disc brake. The brake brings the load to a smooth and

quick stop and holds the load when the motor is not energized. An energized coil releases the hoist

brake.

A load-limiting device (slip clutch) is integrated into the design of the hoist motor brake. Even if the clutch

slips, once power is removed the brake will engage to stop and hold the load.

6.5

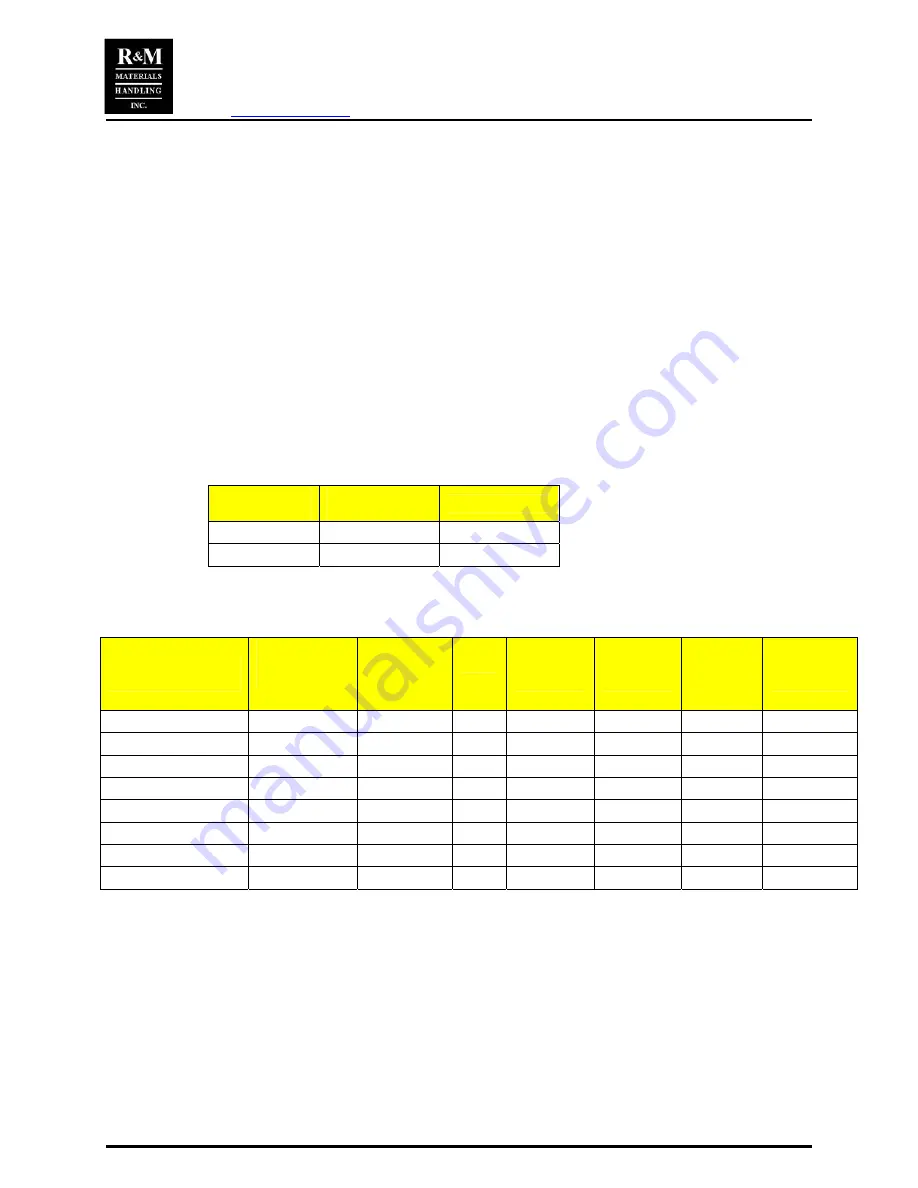

Motor Brake Specifications

MAIN

VOLTAGE

COIL

VOLTAGE

SM10

208 or 230

90 - 100 VDC

320 OHMS

460

190 VDC

1100 OHMS

6.6

SM10 Motor Data – 60HZ MOTORS

POWER

SUPPLY

MOTOR

TYPE

MOTOR

RPM

HP

START

AMPS

NOM.

AMPS

NO

LOAD

AMPS

FIELD

OHMS

208V / 3PH / 60HZ

SINGLE SPD

3600

2.8

230V / 3PH / 60HZ

SINGLE SPD

3600

2.8

33.8

8.6

3.6

2.9

460V / 3PH / 60HZ

SINGLE SPD

3600

2.8

16.5

4.3

1.9

5.1

208V / 3PH / 60HZ

TWO SPD

3600 / 900

2.8

38.9 / 13.2

8.28 / 5.52

3.4 / 5.7

3.3 / 11

230V / 3PH / 60HZ

TWO SPD

3600 / 900

2.8

33.8 / 11

7.2 / 4.8

3.0 / 4.4

3.3 / 11

460V / 3PH / 60HZ

TWO SPD

3600 / 900

2.8

16.5 / 5.5

3.5 / 2.2

1.6 / 2.2

10.6 / 46.4