FDV451 / MQFDV453

Horizontal Vent Installation

1. Use the Venting Table to determine the

minimum distance from the bottom of fireplace

to center of vent. Cut a hole through the wall

allowing for an 11” x 11” (inside diameter) in

combustible walls for wall thimble or an 8”

diameter hole in a non-combustible wall (See

Figure 3).

2. For the clearance to combustible above a 90

degree bend see

Clearance to

Combustibles

section.

3. Select the approximate vent length, precise

measurements are not needed as your flex

pipe can be expanded to twice its shipped

length for ease of installation

4. To install wall thimble center over 11” x 11”

(inch) framing from both sides of wall and

secure. Route flex vent pipe through wall

thimble.

5. Before joining pipes, apply a bead of high

temperature sealant (Mill Pac) to end of pipe.

First attach the four inch (4”) flue pipe to the vent termination with sealant, and secure with the four screws

provided. At this time make sure the spacer springs are attached to the (4”) flex pipe as required. Then attach the

seven inch (7”) pipe by the same method.

6. Mount vent termination and seal to wall using caulking around the wall thimble to weather proof. After installing

the vent termination, double check to make sure the pipe extends properly through wall thimble and into vent

termination.

7. Before joining pipes to fireplace flue, apply a bead of high temperature sealant (Mill Pac) to end of pipe. First

attach the four inch (4”) flue pipe to fireplace with sealant, and secure with the four screws provided. At this time

verify that the spacer springs are attached properly to the (4”) flex pipe as required. Then attach the seven inch

(7”) pipe by the same method.

8. Support horizontal pipes every two (2) feet (61 cm) with metal strap bands. Re-check fireplace to make sure it is

levelled and properly positioned and secured.

9. Support vertical pipes to maintain a minimum of 1” or greater clearance to combustibles with metal strapping

bands.

If finishing the outside wall with vinyl or wood siding it is recommended that a Siding Shield be installed, Part Number

ZDVSSLR.

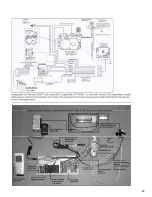

Silicone and Screw

or Clamp

Trim Ring

Decorative Cover

Wall Thimble

Silicone and Screw

or Clamp

Caulk

(Both Sides)

1” top of horizontal vent

1” minimum

2”

top of 90° elbow

All other existing pipes 1” clearance.

Support Straps required to maintain

rise and prevent sagging.

May be installed

in joist area

FIGURE 1

FIGURE 2

11” x 11” Framing

for Combustible wall.

8” Round Hole

through Non-Combustible wall.

FIGURE 3

8” DIA

54”

MINIMUM

THROUGH NON-COMBUSTIBLE WALL

THROUGH COMBUSTIBLE WALL

WARNING:

A

HORIZONTAL

VENT CERTIFIED

GUARD (SAFETY

CAGE) IS

AVAILABLE WHEN

REQUIRED BY

LOCAL CODES.

62

Summary of Contents for Kingsman FDV451LP

Page 42: ...Gas Conversion for Modulator PART C 42...

Page 47: ...Configuration 1 Basic manual HI LO and manual ON OFF capabilities 47...

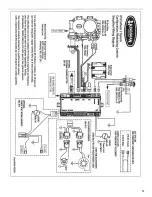

Page 48: ...Receiver Module 584 523 521 221 1001 P221SI Receiver Module 584 523 521 221 1001 P221SI 48...

Page 55: ...Proflame 2 Remote Control 55...

Page 57: ...57...