K10-STANDARD-OP-EN

- 15 -

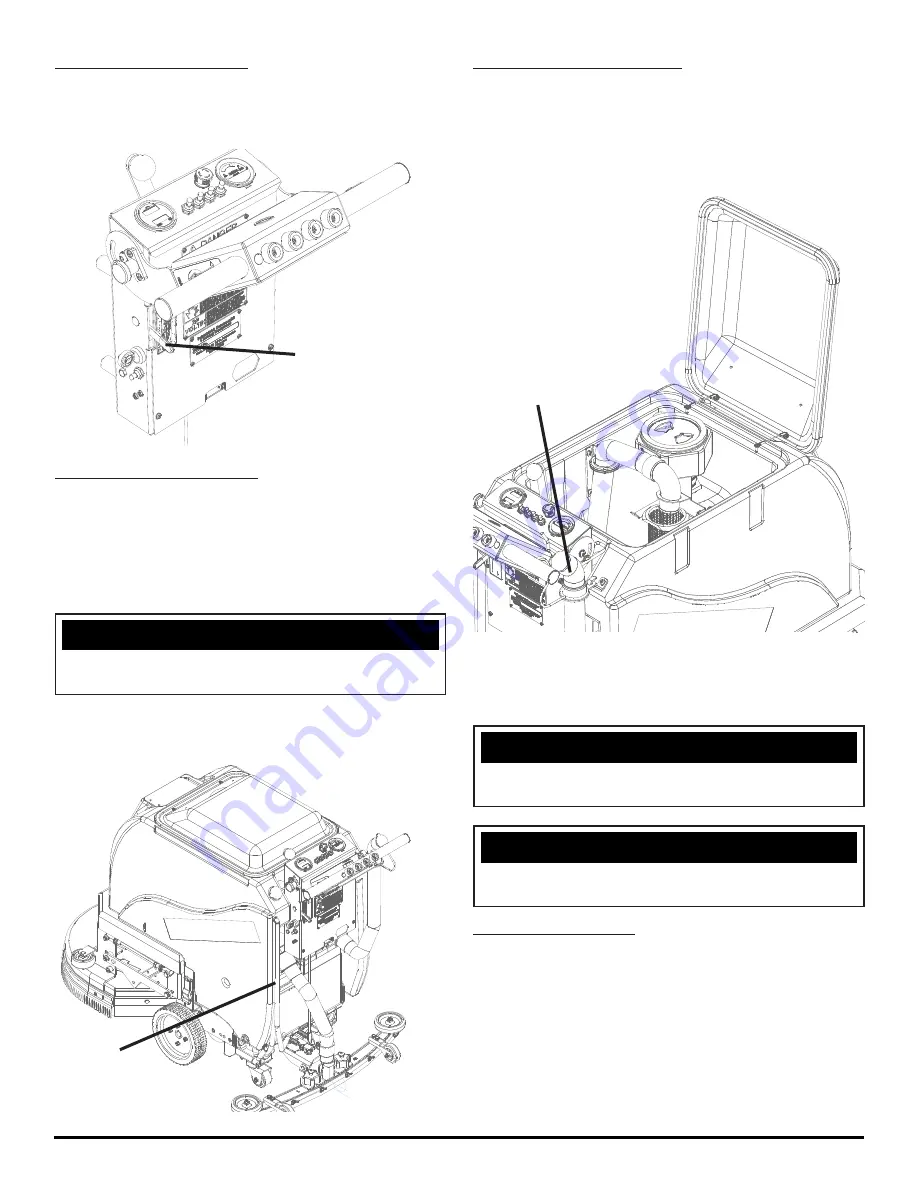

ADJUST SOLUTION FLOW:

1. Push down on the Solution Flow Lever

(A)

to decrease

the solution flow and push up on the lever to increase

solution flow

(SEE BELOW)

.

DRAINING SOLUTION TANK:

To drain unwanted cleaning solution from the Solution

Tank, perform the following steps:

(SEE BELOW)

1. Pull the clear Sight Tube/Drain

Hose

(B)

off barbed fitting.

NOTICE

Get Supervisor APPROVAL first and drain at

APPROVED locations only.

2. Rinse out Tank and solution flow

system with clean water.

DRAINING RECOVERY TANK:

Always empty Recovery Tank when refilling the Solution

Tank. You can refill the Solution Tank while the Recovery

Tank is draining. To drain the Recovery Tank remove Drain

Hose

(C)

from hook at rear of Tank and pop off cap

(SEE

BELOW)

. Rinse with fresh water.

NOTICE

Leave Recovery Lid open while draining Tanks. Rinse

thoroughly.

NOTICE

Get Supervisor APPROVAL first and drain at

APPROVED locations only.

OPEN RECOVERY LID:

1. Rotate Tank Lid

(C)

forward and full open to rest

in a tipped open position

(SEE ABOVE)

.

A

B

C