K10-STANDARD-OP-EN

- 19 -

BATTERY CHARGING

Charger Specifications

•

Output voltage of 24 Volts

•

Output current of 12 amps max

•

Input voltage of 110 Volts/ 60 Hz

(220V/50 Hz available)

•

Automatic shut off circuit

•

Made for Deep Cycle Batteries

DANGER

Explosive hydrogen gas forms when Batteries are

charging. An open flame or spark can cause this gas

to explode. Serious personal injury or property damage

could occur. Only charge the Batteries in this machine

in a well ventilated area.

WARNING

Before you service a Battery, always wear face protec-

tion, protective gloves and protective clothing. Battery

acid or battery explosion can cause serious injuries.

WARNING

The Batteries in this machine contain sulfuric acid,

which causes burns to skin. If battery acid contacts

clothing or skin, rinse the effected area with cold water

immediately. If battery acid gets on your face or in your

eyes, flush the area immediately with cold water and

seek medical attention.

CAUTION

Always use the automatic battery charger provided by

the manufacturer of this machine to charge the batter-

ies of this machine. It is designed to charge the Batter-

ies at the appropriate rate. If you must use a different

charger, disconnect the Batteries before charging to

avoid damage to the electronic speed controller.

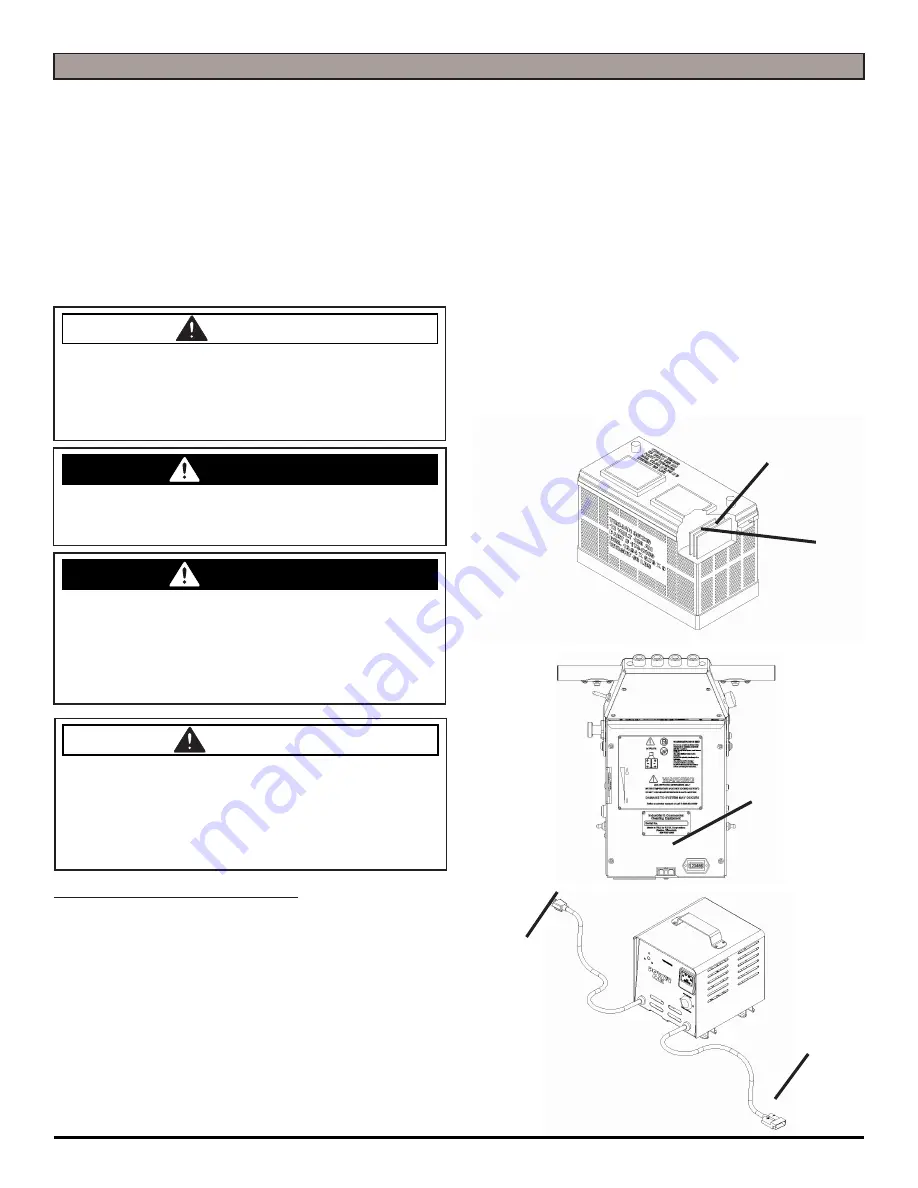

EXTERNAL BATTERY CHARGING:

1. Transport machine to a well ventilated area for

charging.

2. Turn the machine off. Tip Tank back.

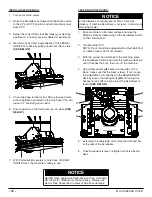

3. Check the water in each battery

(1)

. Do not charge

the machine unless the water is slightly higher than

the plates. If needed, add enough distilled water to

just slightly cover the plates. Be careful not to over fill.

Batteries can overflow during charging. Replace caps

before charging.

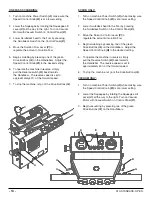

4. First, plug the red 50 Charger plug into the machine’s

Charger Port

(2)

. While the Charger plug is connected,

plug the Charger Power Cord into a grounded 110 Volt

standard wall outlet

(3)

.

5. The Charger will automatically begin charging and

automatically shut off when fully charged

(check

Battery gauge)

.

6. After the Charger has turned off - First, unplug the

Charger from the wall outlet. Second, unplug the red

50 Charger plug from the machine.

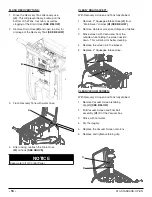

7. Recheck the cell level after charging. If needed, add

distilled water up to the correct level. Be certain to

replace the caps securely and to wipe off the top of the

Batteries with a clean cloth.

WATER LEVEL SHOULD BE

1/8'' ABOVE PLATES

1

2

2

3