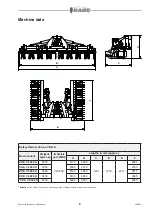

05/2003

3

2

1

4

11

12

Harrows speeds

Power

take-off

rpm

Switch

position

Centre gear

output

Rotary

speed

1000

1

645

249

1000

2

888

344

1000

3

1181

457

Harrows speeds

Harrows speeds and travel speed (max. approx. 8

km/h) definitively influence the desired crumbling

effect. Select the lowest possible speed, which still

provides good results.

High harrows speeds cause increased blade

wear.

Centre control gear:

3 gears

(11/1,2,3).

Attention: only switch when stationary!

For the switching and coupling of the articulated

shaft, the gear/drive strand can be turned with a

box spanner (SW 24) on the hexagon screw at

the gear output of the centre gear

(11/4)

or the side

gear.

Subject to technical modifications