05/2003

16

17

19

15

1

1

2

2

1

4

3

2

1

14

Maintenance

When working on the mounted implement, switch

off the power take-off, switch off the engine and

remove the ignition key!

Do not work on the implement while it is engaged!

- secure the raised implement by additional means

to prevent undesired lowering!

Before performing work on the hydraulic system,

lower the unfolded implement and depressurise the

system!

Dispose of oil properly (mineral-based oils)!

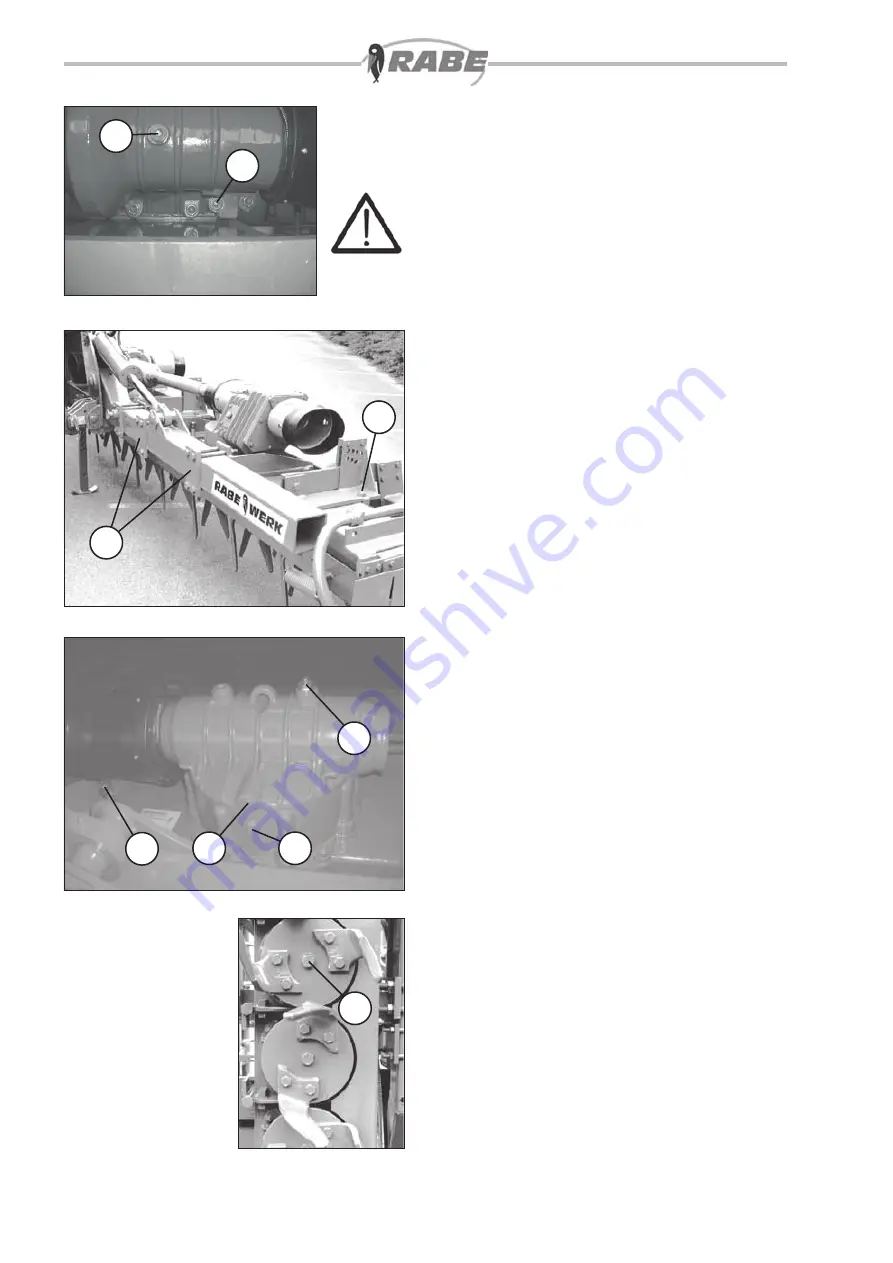

After first use (approx. 8 h) Check all fastening

bolts are tight after first use and then regularly

thereafter - use a torque wrench!

Tighten blade fastening bolts to 380 Nm,

Clamping bolts: (

16/1

) M 20/8.8 – to

425 Nm

(

17/1

) M 16/8.8 – to

210 Nm

(

16/2, 17/2

) M 20/10.9 – to

450 Nm

Tension bolts (

19/1

): ....................... – to

610 Nm

Check the gear unit oil level on a daily basis

while the rotary harrow is in a horizontal position:

Unscrew the oil level control screw and verify that

the oil is at the lower edge of the thread. When

screwing in again, make sure that it is clean.

Centre control gear – control screw (

15/1

),

Side gear – control screw (

17/1

),

Gear box – dip stick (

17/4

),

Visual inspection for leaks.

Attention! The aspirator mounted on the top of

the centre gear (17/3) is not a dip stick for oil

level control!

Regularly lubricate bearings with the lubrication

nipple;

Daily:

Oil the packer roller bearings on the

articulated shafts (as well as the sliding profiles

and protective bearings) according to the

lubrication schedule of the articulated shaft

manufacturer. Oil linkages, ensure ease of

movement of spindles. Improve paint damage.

Check hydraulic hoses regularly and replace if

damaged or embrittled (spare parts list). Hoses

are subject to natural ageing, the period of usage

should not exceed 5-6 years.

After use, clean the rotary harrow and the

implement underside, preserve the blades and

packer roller with anti-corrosive agent.

When water jet cleaning (especially with high

pressure) do not aim directly "at bearings".

Subject to technical modifications