Racepak

Racepak

Racepak

Racepak

949-709-5555

www.Racepak.com

Hardware Installation: Driveshaft Sensor

and Collar

A drive shaft rpm sensor and mounting bracket used to mount the sensor to the vehicle are included in the

Sportsman Kit. However, the drive shaft split collar is sold separately. These collars can be purchased direct from

Racepak and are offered in many different sizes to accommodate multiple yoke configurations. These collars are

available with either two or eight magnets. The rpm sensor is a magnetically sensitive sensor that is polarity

sensitive each time a magnet passes in close proximity.

The first step in installing the kit is to determine where the split collar will be mounted. Normally the split collar is

mounted on the pinion shaft/yoke. However, it can also be mounted on the transmission tail shaft/yoke. If your

transmission and/or bell housing is removed frequently, you should mount the collar on the pinion shaft/yoke. Thus

avoiding possible damage to the sensor during clutch, and/or transmission service.

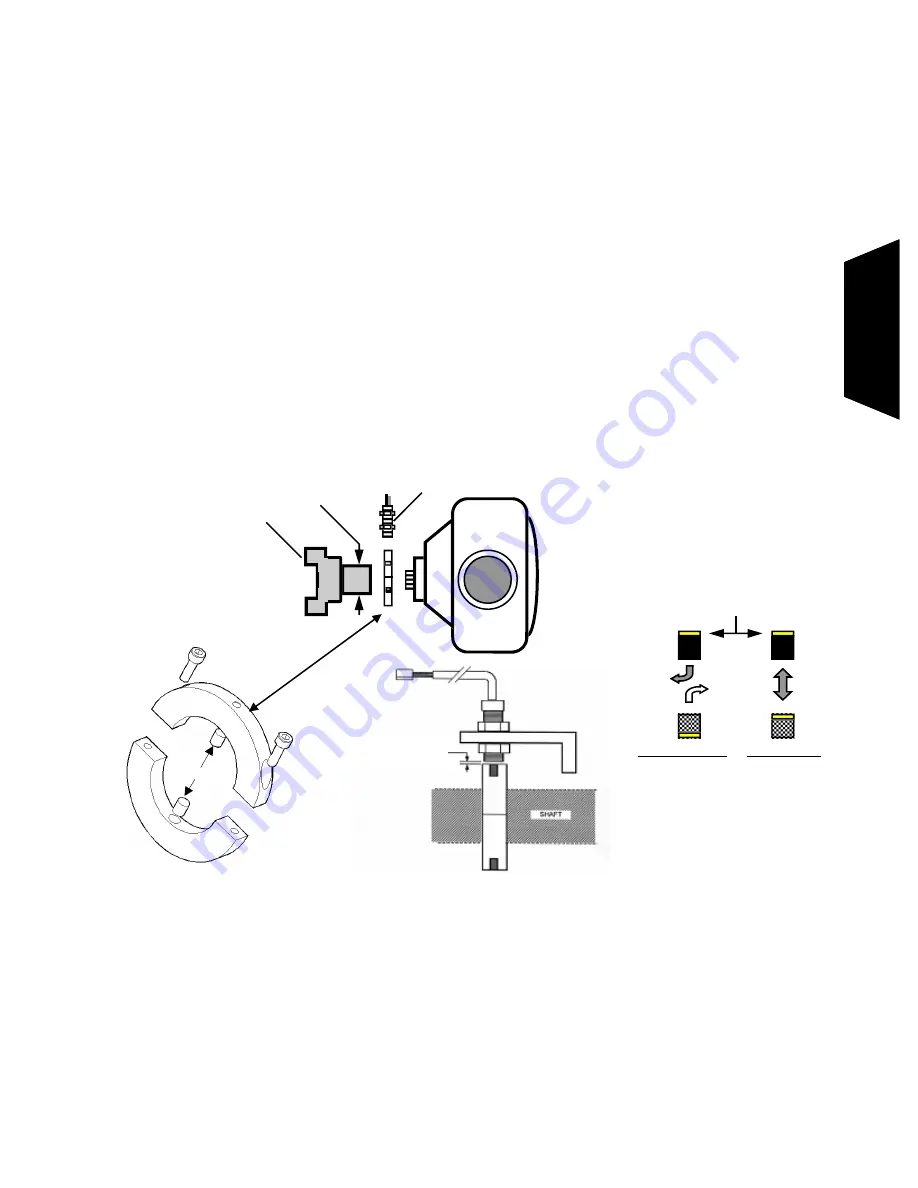

After you have selected a location, position the split collar over the shaft, and fix the collar onto the shaft by

tightening the two bolts connecting the two collar halves. Tighten the two bolts equally such that the gap on both

sides of the split collar is equal. This will ensure the magnets are 180 degrees apart.

Next, secure the mount bracket, and rpm sensor to the vehicle as shown below. The mount must be installed to a

solid member of the vehicle that does not move relative to the placement of the split collar assembly. This will

prevent contact between the sensor and the split collar. Insert the rpm sensor in the slotted hole in the mount

bracket, and position the rpm sensor such that the sensor is centered over the magnet in the split collar. Next,

adjust the gap between the end of the rpm sensor and the split collar between .050” to .100”. Secure the sensor by

tightening the two jam nuts located on the sensor.

NOTE: SPLIT COLLARS ON CARS USING A COUPLER

When the driveline is equipped with a coupler rather than a U-joint, the best location for mounting the split collar often changes. Because most of the

couplers have the female portion mounted on the pinion, and the radius on the backside tapers right to the pinion seal, this does not leave any room to

mount a split collar in the traditional location. In this case, we must move the split collar forward onto the male portion of the coupler.

When mounting the split collar on the male half of the coupler a new problem arises. This portion of the coupler needs to have some longitudinal

movement in order to function properly. It must be able to slide forward and backward a small amount. This presents a problem for the split collar in

trying to keep the magnets positioned under the sensor. When the magnet moves out from under the sensor, the signal is lost and the drive shaft RPM

is not recorded. In order to avoid this problem, Racepak has made collars that contain two pairs of magnets (total of 4). Each pair of magnets is

mounted longitudinally (inline) on the collar, which allows it some freedom to move without the sensor losing contact with a magnet. In most cases,

the male portion of the coupler will have two outside diameters.

These collars are sold separately and are available directly from Racepak.

8

Note:

If you are using a collar other

than the one supplied by Racepak

you can use the supplied magnet

with the sensor to test the polarity

of the magnets in the collar

.050 to .100 clearance

between sensor and magnet

Sensor

U-Joint Yoke

Rear

End

MEASURE YOKE

O.D. HERE

Yellow Painted End

INCORRECT

Magnets

will repel

each other

CORRECT

Magnets

will attract

each other

Magnets

Yoke is shown separated from pinion.

In most cases, installation does not

require yoke to be removed

H

a

rd

w

a

re

In

st

a

ll

a

ti

o

n