11

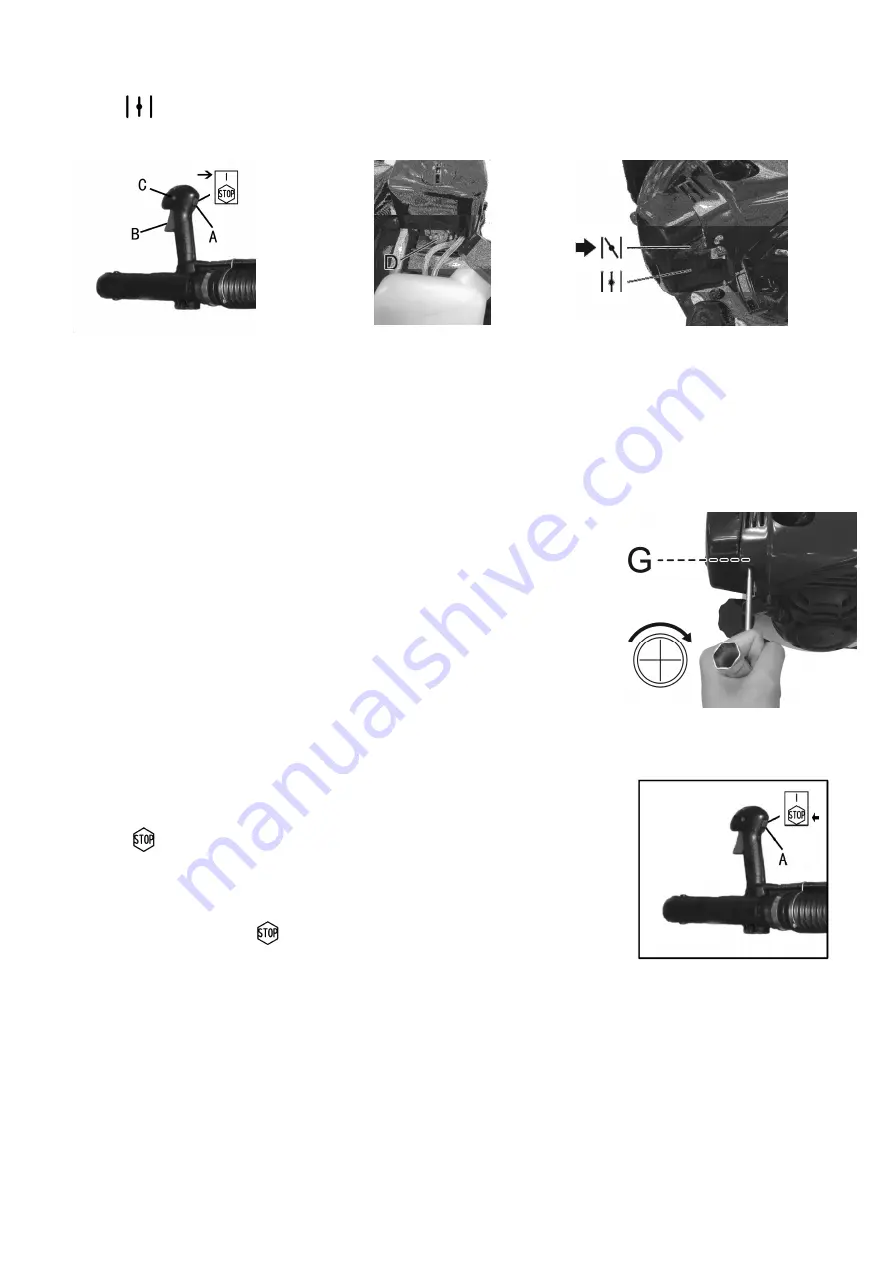

5. Pull the starter rope 4-6 times – if unit does not start, move choke lever to PARTIAL CHOKE by setting it between

the two choke positions. Pull starter rope 4-6 more times. Wait 10 sec. after unit starts, then move choke lever to

RUN “ “.

6. Push the lock-out button (C) and press throttle trigger (B) to run.

Fig.9 Fig.10 Fig.11

NOTE:

If engine fails to start after repeated attempts, refer to Troubleshooting section.

NOTE:

Always pull starter rope straight out. Pulling starter at an angle will cause rope to rub against the eyelet. This

friction will cause the rope to fray and wear more quickly.

NOTE:

Always hold starter handle when rope retracts. Never let a rope snap back from an extended position. This

could cause the rope to snag or fray and also damage the starter assembly.

5.2 Important idling information

In some cases due to operating conditions (altitude, temperature etc.) your blower

may need a slight adjustment to the idle speed. After warming up, if unit does not

idle after restarting 2 times, follow these steps to adjust idling.

1. Locate the idle adjustment screw (G) on the carburetor (Fig.12).

2. Using a Phillips or slotted screwdriver, turn screw 1/4 to 1/2 turn clockwise (to

the right). Unit should then idle properly.

Fig.12

5.3 Stopping the engine

5.3.1 Emergency stopping procedure

When it is necessary to stop blower engine immediately, PRESS the

OFF “STOP “switch (A) (Fig.13).

5.3.2 Normal stopping method

For normal stopping, release trigger and allow engine to return to idle speed.

Then PRESS the OFF “STOP “switch (A) (Fig.13).

Fig.13

5.4 Starting a warm engine (Engine has been stopped for no more than 15-20 minutes)

1. Set throttle latch (see step 2 for starting a cold engine), pull starter rope briskly.

2. If engine does not start, or starts and then stops after 5 rope pulls, follow procedure “STARTING A COLD

ENGINE”.

Summary of Contents for RAC26BPB

Page 17: ...17...