4. FILLING FUEL TANK

WARNING! Gasoline is extremely flammable.

Store fuel in specially designed cans for this purpose.

Fill the fuel tank only outdoors and before starting the engine. Do not smoke when filling the fuel

tank or handling fuel.

Never open the fuel tank cap and never add fuel while the engine is running or when it is hot.

If fuel has spilled, do not start the engine any further, move the tool away from where the fuel has

been spilled, and be careful not to create a spark or flame until the fuel vapors have dissipated.

Fully close all fuel tank and fuel canisters.

Before tilting the mower to maintain the blade or drain the oil, empty the fuel tank.

WARNING: Never fill the fuel tank indoors, while the engine is running, or before the engine has

cooled down for at least 15 minutes after use.

CAUTION: Do not use unapproved gasoline, such as E15 and E85. Do not mix the oil with gasoline

or modify the engine to operate with alternative fuels. The use of unapproved fuels will damage the

engine parts and will void the engine warranty. To protect the fuel system from scale formation, add

a fuel stabilizer to the fuel. All fuels are not identical. If start-up or performance problems occur,

change supplier or fuel brand.

4.1 FILLING TANK

Fuel must meet the following criteria:

- Clean, new and lead-free gasoline.

- A minimum octane rating of 87/87 AKI (91 RON). For use at high altitudes, see below

- A gasoline containing up to 10% ethanol is acceptable.

- Remove the fuel tank cap. Add fuel.

- Close the fuel tank with the cap.

Do not overfill. Wipe off any fuel that has overflowed before starting the engine.

4.2 ENGINE OIL

Recommended oil: We recommend the use of high-quality detergent oil classified for SF, SG, SH, SJ or

higher. Do not use special additives.

Filling oil tank

- Open the oil tank.

- Fill directly the oil in the tank. Do not overfill.

- Close the oil tank. Wipe any spillage.

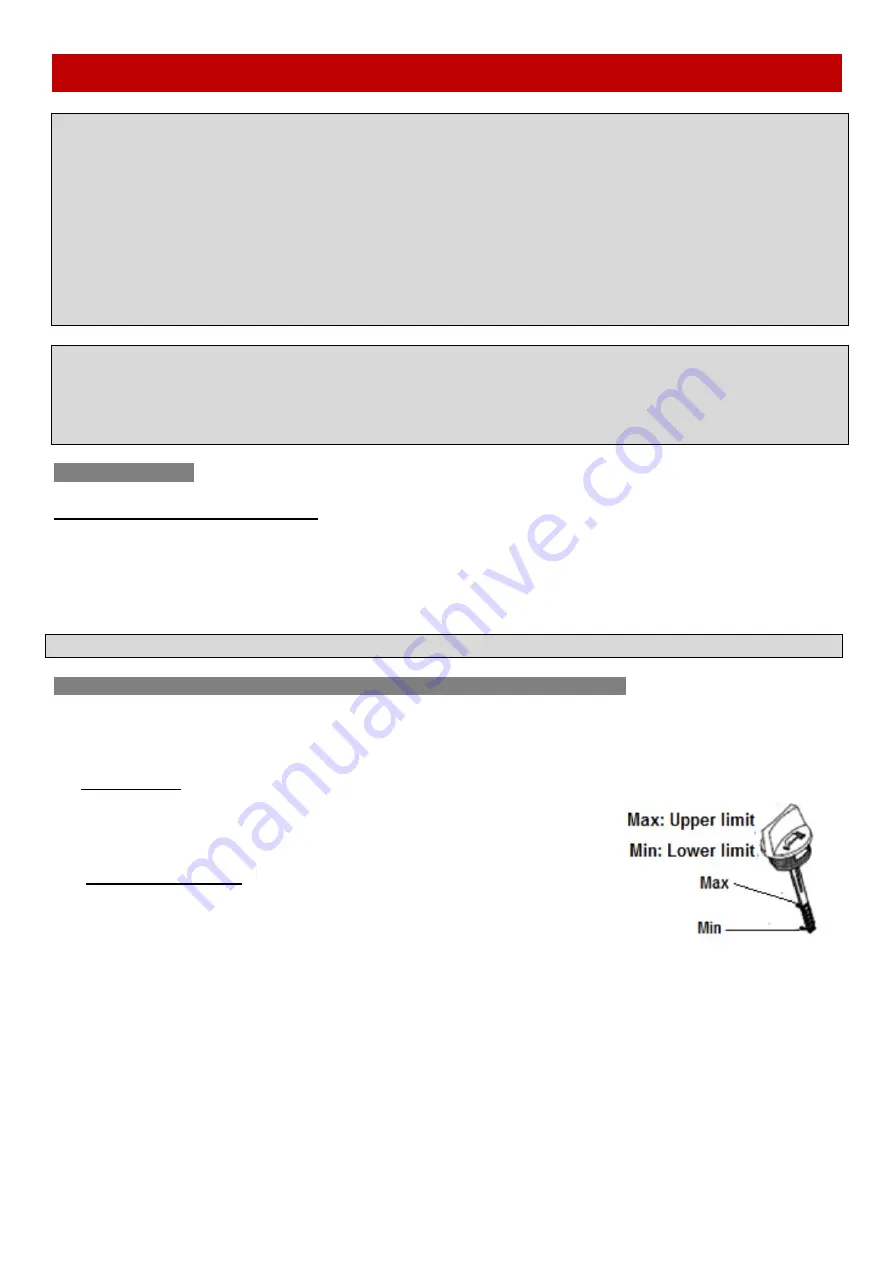

Checking the oil level

- Check the oil level when the engine is off and horizontal.

- Remove the plug / dipstick from the oil tank and wipe it off.

- Insert the oil tank plug / dipstick into the tank neck as shown,

without screwing it in, and then remove it to check the oil level.

- If the oil level is near or below the lower limit of the dipstick,

remove the dipstick and fill the recommended oil reservoir up to

the upper limit of the dipstick (bottom edge of the dipstick). Do

not overfill.

- Replace the oil tank plug / dipstick.

12