17

A-FRAME INSTALLATION

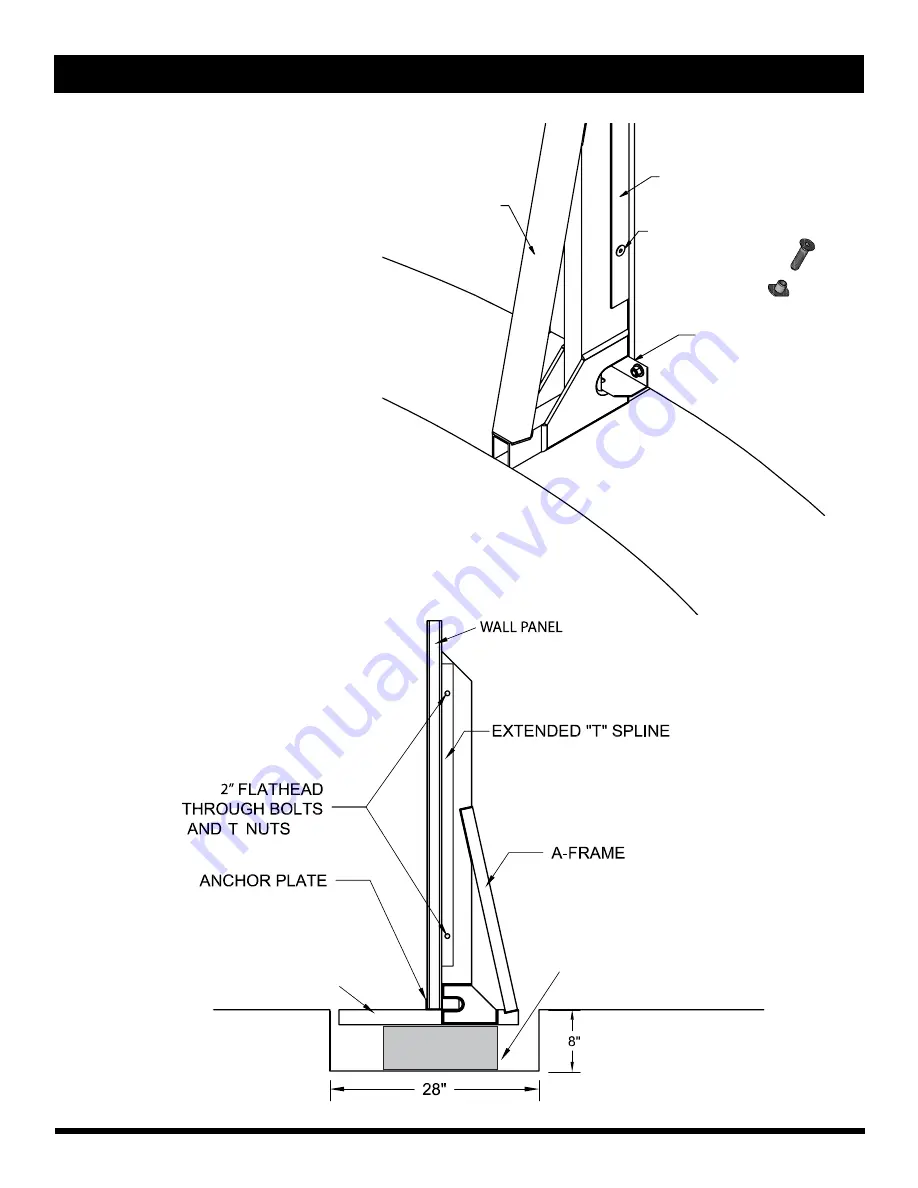

There are 8 A-frames per Freeform pool.

The horizontal base of the A-frame will be under

the wall panel and the A-frame anchor plate.

The A-frame vertical will interlock inside the

extended (T) splines at the wall connections.

Secure A-frame to extended (T) splines with

two (2) 2” flathead through bolts and T nuts.

Do not over tighten.

2” Flathead Through

Bolt & T Nut

Extended T Spline

Anchor

Plate

A-Frame

Position hold down plates so that A-frame horizontal is

covered in the interior of the pool. Pre-drill holes and then

attach to horizontal using the sheet metal screws included.

TRENCH

w/CONCRETE BLOCK

EARTH

POOL INTERIOR

A-FRAME HORIZONTAL