INSTALLATION INSTRUCTIONS

13

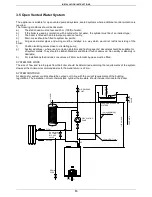

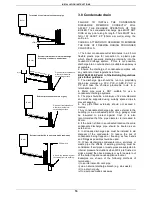

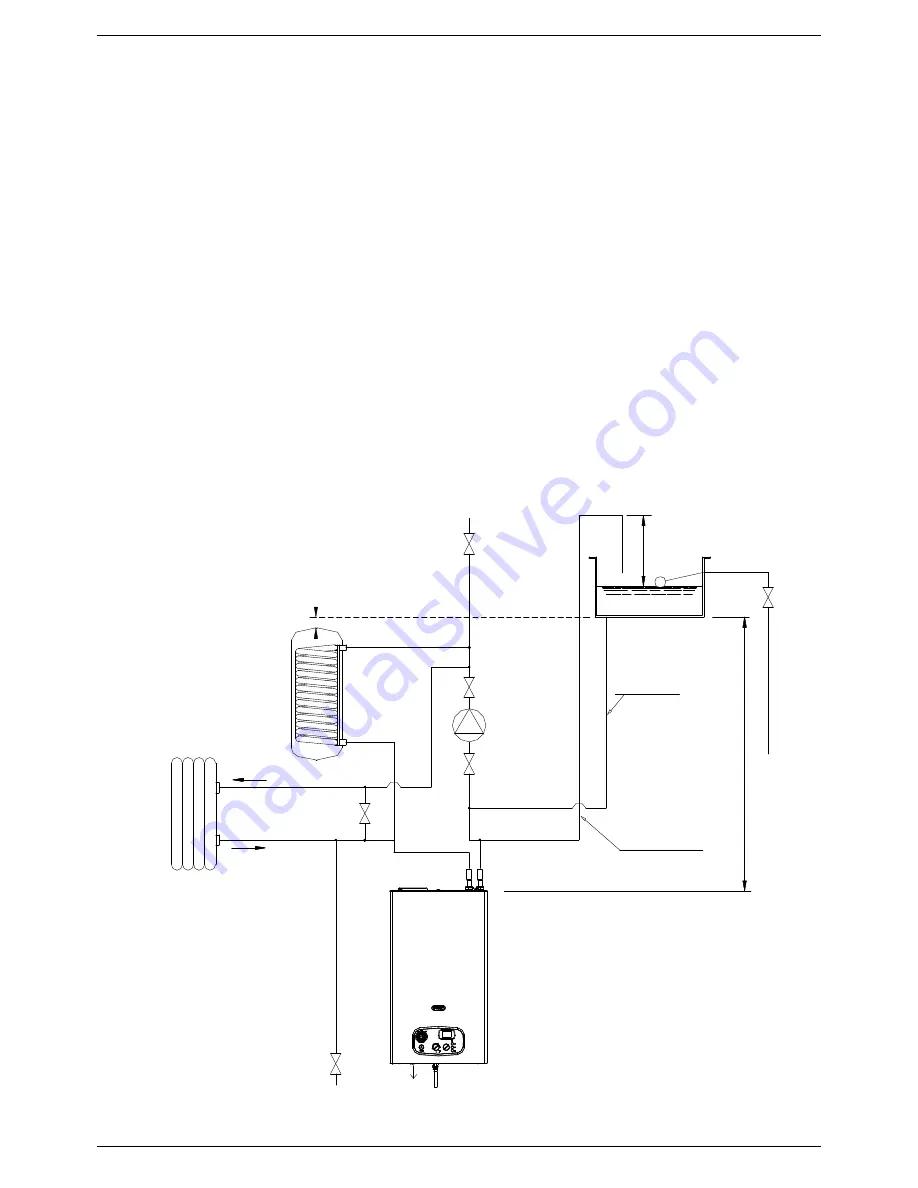

3.5 Open Vented Water System

The appliance is suitable for open vented pumped systems, sealed systems where additional control protection is

required.

The following conditions should be observed:

a)

The static head must not exceed 30 m (100ft) of water;

b)

If the boiler is used in conjunction with a cylinder for hot water, the cylinder must be of an indirect type;

c)

The boiler is fitted with an internal pump overrun facility;

d)

Drain cocks should be fitted to system low points;

e)

All gas and water pipes and wiring must be installed in a way which would not restrict servicing of the

boiler;

f)

Position isolating valves close to circulating pump;

g)

System additives – where used, corrosion inhibitors and flushing agents / descalers should be suitable for

all system metals. They should be British Standars and Water Council approved. Non acidity or alkalinity is

desirable;

h)

For installations that include zone valves a 22 mm automatic by-pass must be fitted.

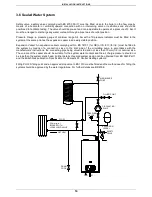

SYSTEM PIPE WORK

The size of flow and return pipes from the boiler should be determined according the requirements of the system.

However the minimum recommended size for flow and return is 22 mm.

SYSTEM CONTROLS

All designs for system controls should be carried out in line with the current requirements of the building

regulations. The installation of room thermostats, cylinder thermostats, should include interlock to the boiler.

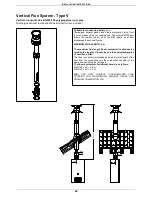

22 mm (min.)

DRAIN

COCK

AUTOMATIC

RETURN

BYPASS

FLOW

22 mm VENT (min.)

COLD FEED

15 mm (MINIMUN)

FEED AND EXPANSION

CIRCULATING

PUMP

CISTERN

POINT

AIR RELEASE

H

E

IG

H

T

4

5

0

m

m

M

IN

.

V

A

L

V

E

S

E

R

V

IC

E

C

O

L

D

M

A

IN

1

1

5

0

m

m

M

IN

.

6

0

0

m

m

.

M

IN

.

HF

HR

G

CD

VALVE