INSTALLATION INSTRUCTIONS

15

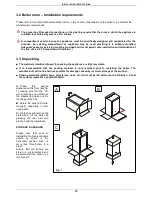

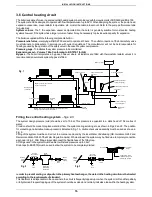

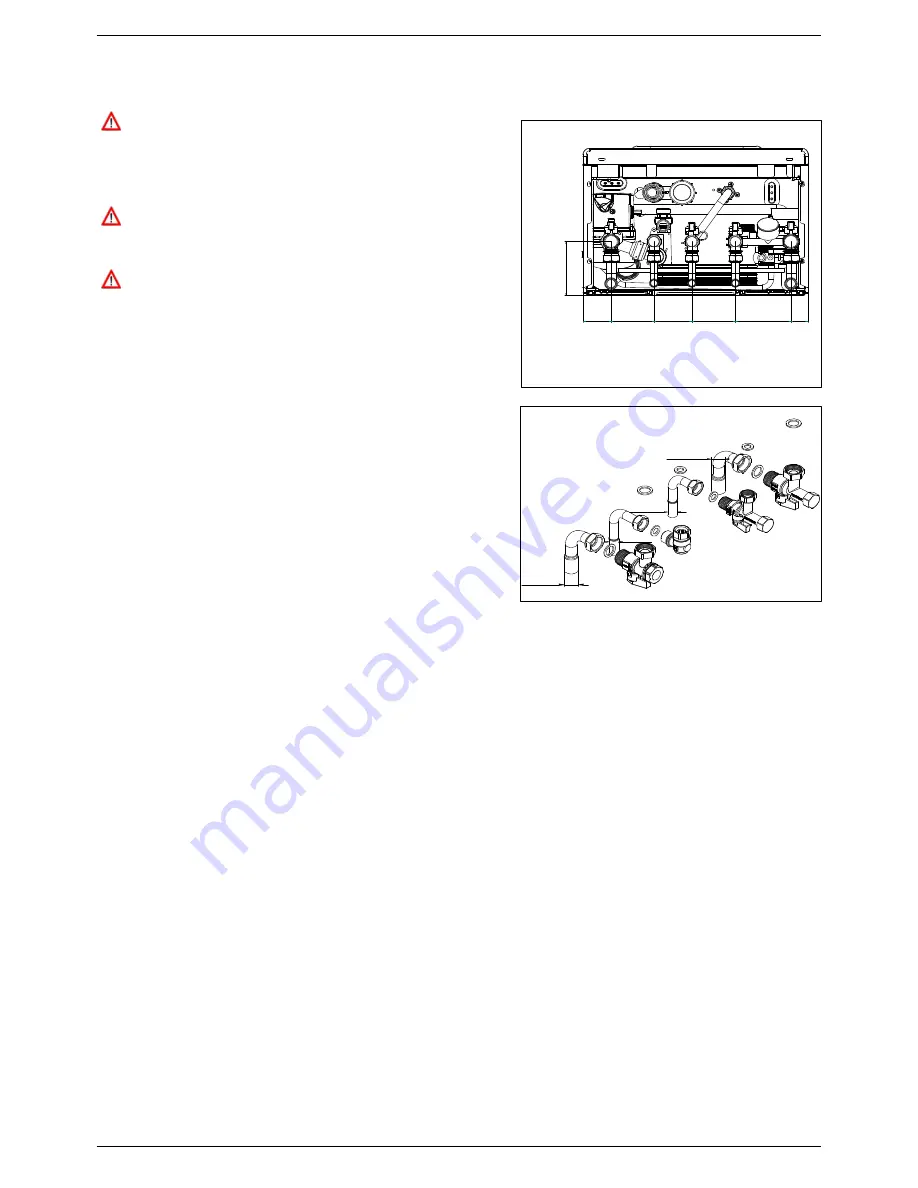

3.5 Water connections

In order to safeguard the heat exchanger and circulation

pump, especially in case of boiler replacement, it is

recommended that the system is hot-flushed to remove

any impurities (especially oil and grease) from the pipes

and radiators.

Make sure that the domestic water and central heating

pipes are not used to earth the electrical system. The

pipes are totally unsuitable for this purpose.

The

Isolation Valves provided must be installed

on the heating and D.H.W circuits. This will facilitate all

maintenance and service operations where the boiler

needs to be drained.

■

To prevent vibration and noise coming from the system, do

not use pipes of reduced diameter, short radius elbows or

severe reductions in the cross sections of the water

passages.

■

In order to guarantee the reliability of the boiler and prevent

permanent damage in areas with very high water inlet

pressure a 2.5 bar pressure reducing valve should be fitted.

■

To facilitate the installation, the boiler is supplied with a

hydraulic connection kit (see fig.2).

Domestic hot water circuit

■

In order to prevent scaling and eventual damage to the D.H.W

heat exchanger, the mains water supply must not have a

hardness rating of more than 17.5 °Ck. It is nevert heless

advisable to check the properties of the water supply and

install the appropriate treatment devices where necessary

.

The cold water supply pressure at the inlet to the boiler must be between 0.5 and 6 bar.

In areas with higher water inlet pressure a pressure reducing valve must be fitted before the boiler.

The frequency of the heat exchanger coil cleaning depends on the hardness of the mains water supply and the

presence of residual solids or impurities, which are often present in the case of a new installation. If the

characteristics of the mains water supply are such that require it to be treated, then the appropriate treatment

devices must be installed, while in the case of residues, an in-line filter should be sufficient.

All D.H.W. circuits, connections, fittings, etc. should be fully in accordance with relevant standards and water

supply regulations.

Guidance G17 to G24 and recommendations R17 to R24 of the Water Regulation Guide.

Central heating circuit

In order to prevent scaling or deposits in the primary heat exchanger, the mains supply water to the heating circuit

must be treated according to the requirements of local standards.

This treatment is indispensable in the case where the circuit is frequently topped-up or when the system is often

either partially or fully drained.

The outlet connection of the boiler safety valve must be connected to a discharge pipe with a continuous fall from

the boiler to outside. It must terminate in a safe position where any water, possibly boiling, can discharge without

causing a hazard. The manufacturer will not be held responsible for flooding or damage caused by the operation of

the safety valve in the case of system overpressure.

Condensate Drain

The condensate drain flexible pipe supplied with the boiler (conforming to UNI EN 677 standard) must be

connected to a proper condensate trap. The condensate discharge into the drainage system is allowed providing a

condensate trap (siphon) is installed.

Any condensate discharge pipe work external to the building (or in an unheated part of it) must be insulated to

protect against frost. Before switching the boiler On, check the correct condensate discharge.

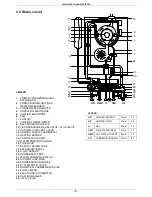

HF

CWI

G

HWO

HR

49

78

70

80

102

31

1

0

5

Fig. 2

Fig. 1

Ø 15 mm

Ø 22 mm

HF

CWI

HR

HWO

Ø 22 mm

Ø 15 mm