INSTALLATION INSTRUCTIONS

17

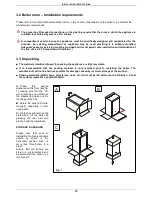

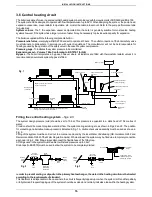

3.7 Condensate drain

FAILURE

TO

INSTALL

THE

CONDENSATE

DISCHARGE

PIPEWORK

CORRECTLY

WILL

AFFECT THE RELIABLE OPERATION OF THE

BOILER. The condensate discharge pipe MUST NOT

RISE at any point along its length. There MUST be a

fall of AT LEAST 2.5° (50mm per metre) along the

entire run.

CAREFUL ATTENTION IS REQUIRED TO MINIMISE

THE RISK OF FREEZING DURING PROLONGED

COLD SPELLS.

I. The boiler condensate outlet terminates in a 25 mm

flexible plastic pipe for connection to a plastic pipe

which should generally discharge internally into the

household drainage system. If this is not possible,

discharge into an outside drain or suitable soak-away is

acceptable.

2. Ensure the discharge of condensate complies with

any national or local regulations in force.

BS 6798:2000 & Part H I of the Building Regulations

give further guidance.

3. The discharge pipe should be run in a proprietary

drain pipe material e.g. PVC, PVC-U, ABS, PVC-C or

PP and take the shortest practicable route to a

termination point.

4. Metal pipe work is NOT suitable for use in

condensate discharge systems.

5. The pipe should be a minimum of 22 mm diameter

and must be supported using suitably spaced clips to

prevent sagging.

6. Any pipe fitted externally should not exceed 3

metres.

7 Any condensate discharge pipe work external to the

building (or in an unheated part of it e.g. garage) must

be insulated to protect against frost. It is also

recommended that the pipe diameter is increased to

32mm.

8. If the boiler is fitted in an unheated location the entire

condensate discharge pipe should be treated as an

external run.

9. In alI cases discharge pipe must be installed to aid

disposal of the condensate. To reduce the risk of

condensate being trapped or freezing, as few bends

and fittings as possible should be used.

10. When discharging condensate into a soil stack or

waste pipe the effects of existing plumbing must be

considered. If soil pipes or waste pipes are subjected to

internal pressure fluctuations when WC's are flushed or

sinks emptied then back-pressure may force water out

of the boiler trap and cause appliance lockout.

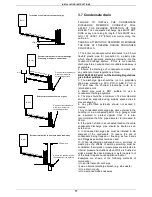

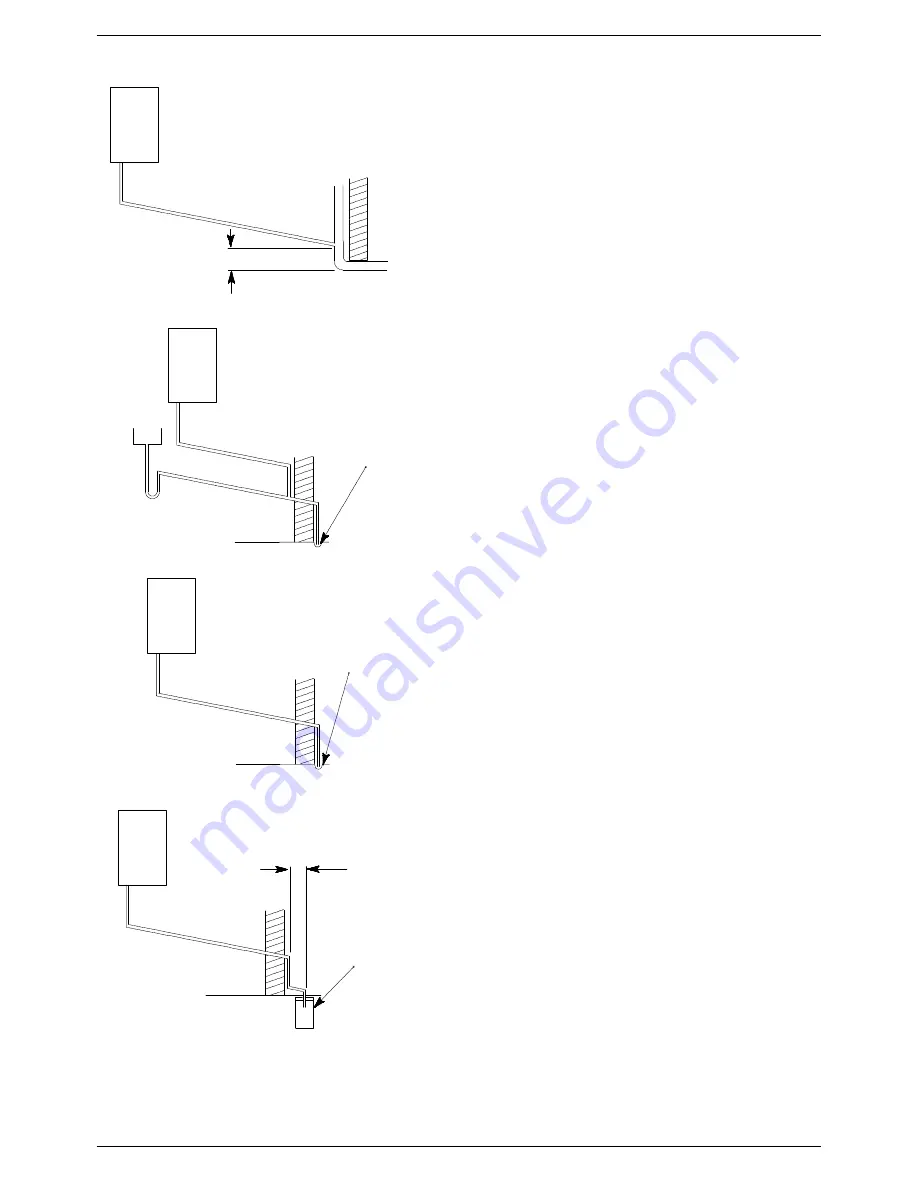

Examples are shown of the following methods of

termination:-

i) to an internal soil & vent pipe

ii) via an internal discharge branch (e.g. sink waste)

iii) to a drain or gully

iv) to a purpose made soak away

450mm min

Holes in the soak-away must

face away from the building

500mm min

External termination to a purpose made soak-away

External termination to a drain or gully

Pipe must terminate above

water level but below

surrounding surface

50mm pe

r metre of p

ipe run

2.5° Minim

um fall

50mm per

metre of p

ipe run

2.5° Minimu

m fall

Boiler

Pipe must terminate above

water level but below

surrounding surface

50mm per

metre of p

ipe run

2.5° Minimu

m fall

External termination via internal discharge

branch e.g. sink waste - downstream

Sink

2.5° Minim

um fall

50mm per

metre of p

ipe run

Termination to an internal soil and vent pipe

Boiler

Boiler

Boiler