Installation Manual

Combi - cod. 99943NA – November 2002

18

MAINTENANCE

To keep the boiler in efficient and safe operating condition, we

recommend you perform the following checks at least once a

year:

•

Check all seals on the gas side and replace gaskets to

restore perfect seal as required.

•

Check all seals on the water side and replace gaskets to

restore perfect seal as required.

•

Visually check combustion and the combustion chamber;

dismantle and clean the chamber if necessary.

•

Check the primary exchanger and clean it if necessary.

•

Check functioning of gas safety systems: Insufficient gas

safety device (flame detection sensor for electronic ignition

boilers) thermocouple for pilot light boilers.

•

Check functioning of heating safety systems: safety

thermostat for temperature limit, safety sensor for pressure

limit.

•

Check the exhaust flue safety device

•

Check the max. and min. modulation pressures and the

modulation.

•

Check that the electrical connection conforms to the

description in the instruction manual for the boiler.

•

Check the domestic hot water flow rate and

temperature.

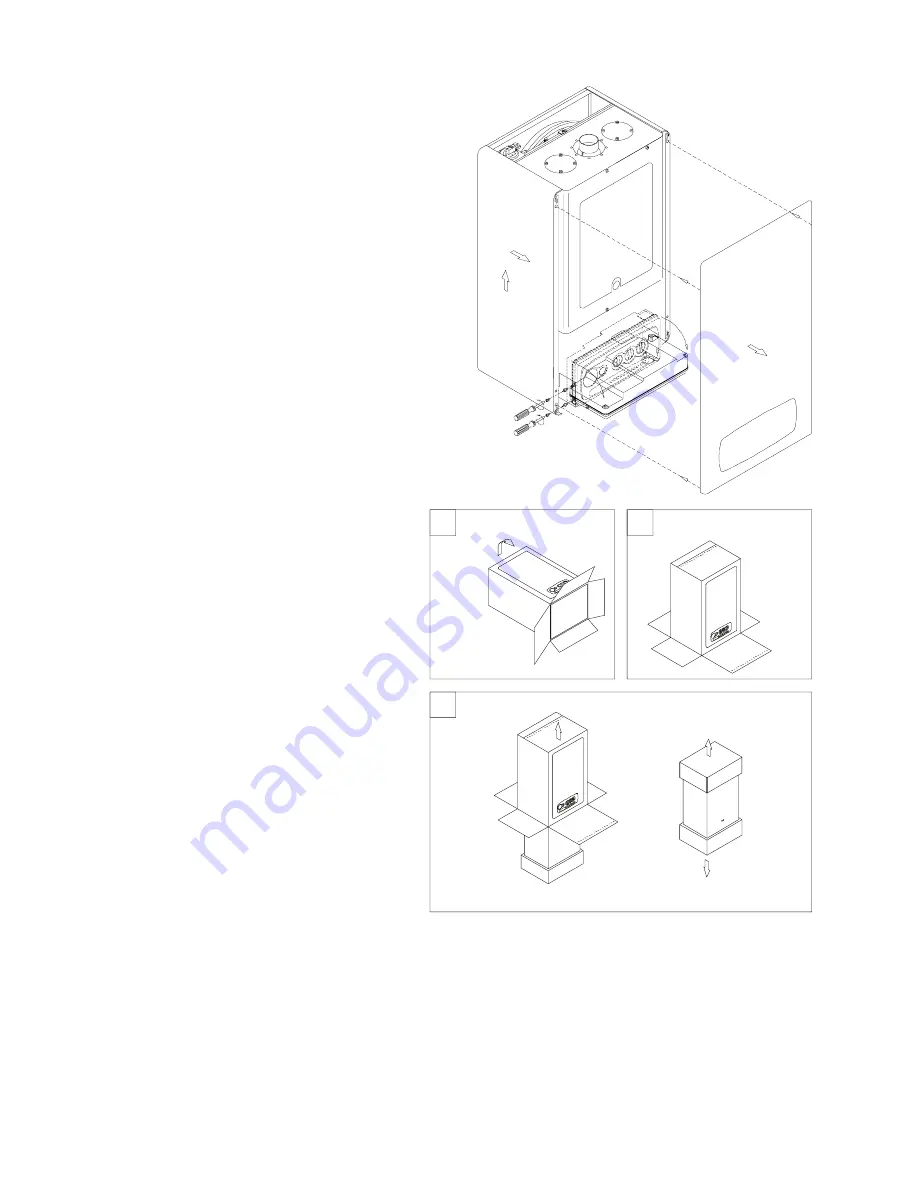

When dismantling the boiler casing, be careful when

removing the side panels after having removed the front

panel; the front panel is removed by undoing the lower

and front fixing screws and then removing as shown in

fig.1, lifting it and then pulling it away. The new side

panels are connected to the frame by means of two

hooks which correspond with two slots on the frame to

ensure quick and efficient fixing

UNPACKING

A.

Set the packed boiler (fig. 2) down on the floor

making sure that the arrow is pointing upwards and

remove the sticking tape. Open the 4 flaps

outwards.

B.

Turn the boiler 180° supporting it by hand.

C.

Lift the boiler with the packing pieces positioning it

vertically in order not to damage the lower corners

of the casing and remove the packing pieces. Lift

the boiler by holding it at the back and proceed with

installation.

N.B.

It is recommended that the boiler be unpacked before installation. The manufacturer cannot be held responsible for any

damage caused to the boiler due to incorrect handling of the boiler.

IMPORTANT!

The packing materials (cardboard) are recyclable.

IMPORTANT!

The inner packing materials (plastic bags, polystyrene foam, nails etc.) are potentially dangerous and must not be left within

reach of small children.

2

1

Fig. 2

A

B

C

Fig. 1

Summary of Contents for RSF 24 E

Page 2: ......