Installation Manual

COMBI - TA01A011.B1003

2

TECHNICAL DATA

Type C unit

Type C devices are devices in which the combustion circuit (air

intake, combustion chamber, exchanger, combustion exhaust)

is sealed off from the place where they are installed.

CENTRAL HEATING - DOMESTIC HOT WATER

sealed combustion circuit type

RSF 30 E -

electronic ignition

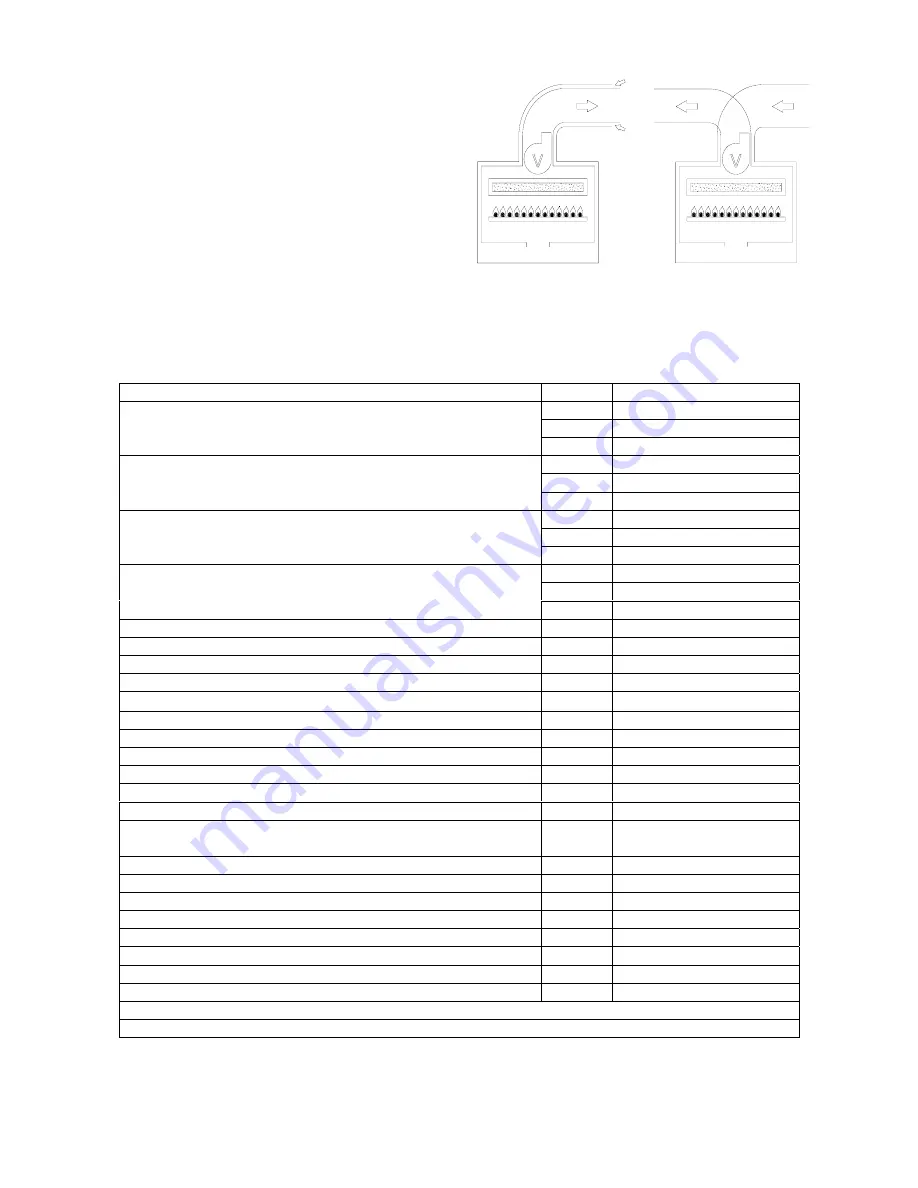

Technical data

MODEL

RSF 30 E

Maximum rated input

kcal/h

29670

kW

34.50

BTU/h

117731

Minimum rated input

kcal/h

16340

kW

19

BTU/h

64837

Maximum rated output

kcal/h

27440

kW

31.90

BTU/h

108882

Minimum rated output

kcal/h

14560

kW

16.90

BTU/h

57774

Heating temperature adjustment

°C

30-80

Max. working pressure (heating)

bar

3

Min. working pressure (heating)

bar

0.3

Expansion vessel capacity (initial pressure 1 bar)

Litres

10

Hot water flow rate

∆

t 30°

Litres 15.24

Max. working pressure (water)

bar

6

Min. working pressure (water)

bar

0.5

Width mm.

450

Height mm.

800

Depth mm.

320

Weight Kg.

49

Coaxial exhaust flue diameter

Double exhaust flue diameter

Ø

Ø

125/80

80/80

Flow/return connections

Ø

3/4” - 3/4”

Cold water connections

Ø

1/2”

Hot water connections

Ø

1/2”

Gas connections

Ø

1/2”

Electrical connection 50 Hz

V

230

Power supply

W

170

Burner jets NP 17 G20

Ø

1.20

Burner jets NP 17 G30

Ø

0.75

Gas category:

IT II2H3

Gas supply pressure:

G20

20 mbar /

G30/31

29-30/37 mbar

FORCED CIRCULATION

Coaxial vertical

Coaxial horizontal

C32

C12

C52 Double

Summary of Contents for RSF 30

Page 2: ......