42

Radijator Inženjering DOO, 36000 Kraljevo, Živojina Lazića Solunca br.6, Srbija

tel. +381 36 399 140, fax. +381 36 399 150,

, e-mail: radijator@radijator.rs

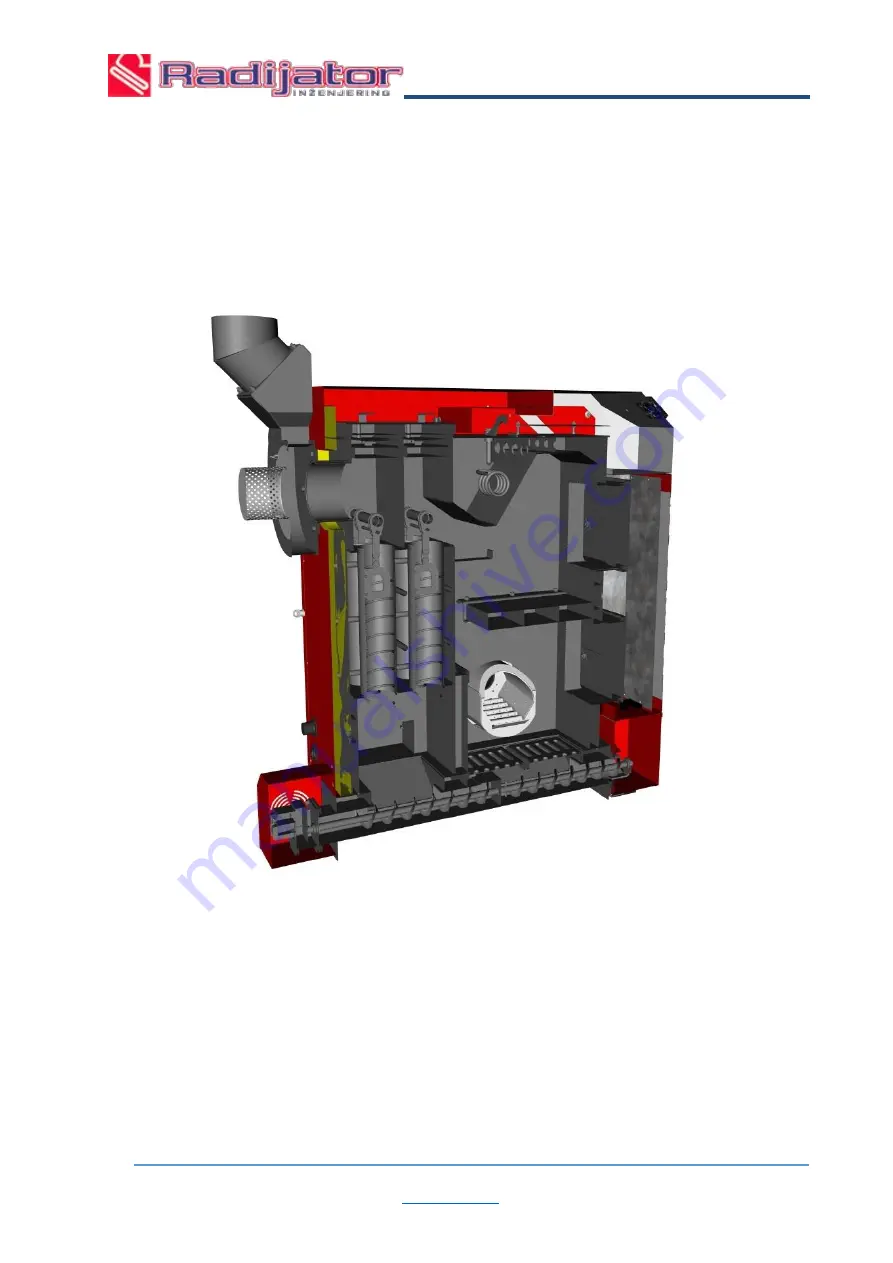

3. Construction

By its combustion mode,

BIOmax PRO

boiler belongs to a group of boilers where the pellet

enters the combustion chamber from the side (

Figure 1, pos. 2 and 3

). During the transport of

pellet from the silo (

Figure 1, pos.5

) to the combustion chamber, the pellet is transported by

the upper and lower screw and by cell transporter between the screws (

Figure 1, pos.4

). On

the entire route, there is no free fall of the pellet and it is always pushed by the force of the

screw. This is an important feature that ensures the reliable functioning of the entire system.

Figure 2

. Cross-section of BIOmax PRO boiler

The water portion of the boiler, with its type of heat exchange between flue gases and water, is

adjusted to biomass. The exchanger is a three-draft exchanger with vertically placed pipes (

see

it on Figure 2

). Inside the pipe there are spiral turbulators with dual function. The first function

is to increase the exchange of flue gases and heat exchanger, while the second function is to

mechanically clean the pipe walls. The movement of the turbulators inside the pipes is achieved

by electric motors (

Figure 3a

) automatically operated at specific intervals.

In the base of the boiler, in the zone below the combustion chamber, there is a screw that expels

ash into the ash bin (

Figure 3b

). This screw conveyor is also motor-activated and operated

automatically.