45

Radijator Inženjering DOO, 36000 Kraljevo, Živojina Lazića Solunca br.6, Srbija

tel. +381 36 399 140, fax. +381 36 399 150,

, e-mail: radijator@radijator.rs

The basic requirements to be complied with during the installation:

-

The boiler can be connected to an open system of central heating, but also to a closed

system of central heating. In case of connection to a closed system, it is recommended

to install the valve for thermal insurance, which is determined by the respective laws of

each state in which the boiler is connected.

-

The boiler must be located at a safe distance from combustible materials.

The boiler must be far enough from possible obstacles in the boiler room for cleaning

and maintenance.

-

Electric power for the boiler is 230V, 50Hz and connection of all devices that the boiler

has should be done according to valid regulations and connection is done by a person

with proper authority.

-

Connection to the chimney also done according to the binding regulations and

manufacturer's recommendations as can be seen below.

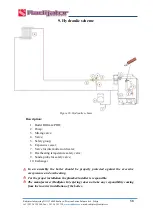

4.2. Measures and safety devices for boilers BIOmax PRO

For safe operation of boiler, it is necessary to assemble and maintain the following elements in

working condition:

-

Pressure

Safety valve (figure 4)

Figure 4. Figure 5. Figure 6.

Pressure safety valve must be of nominal diameter of 1/2 inch calibrated to a maximum

of 3 bars.

This security element which belongs to the group of pressure limiters must be of such

construction to withstand short-term overdrafts and temperatures and pressure as well

as the content in the liquid glycol for heating.

Usually in the same place the vent (

Figure 5

) and the pressure gauge (

Figure 6

) are

connected so that these three elements together constitute a security group and can be

mounted over T'' connector.

This safety element must be subjected to periodic re-calibration, of which the investor,

i.e. the user of the boiler must have valid documentation.

Safety valve must be mounted on the highest point directly to the boiler and the boiler

without any pipeline or any other elements in between. For this purpose there is a

specially designed connector (see picture). Any reduction in diameter of the connector

is prohibited.

The safety valve must have a nameplate and the following information on it

o

Name of manufacture;

o

Designation of type of safety valve / year of testing;