46

Radijator Inženjering DOO, 36000 Kraljevo, Živojina Lazića Solunca br.6, Srbija

tel. +381 36 399 140, fax. +381 36 399 150,

, e-mail: radijator@radijator.rs

o

Nominal flow rate;

o

Data for which thermal effect the safety valve is set;

o

The highest opening pressure 3 bars.

It is obligatory to check the correct functioning at regular intervals as well as the re-

calibration by certified companies. These responsibilities are carried out in accordance

with the law of every country in which the boiler is assembled. Always keep the written

documentation of the last calibration data for the safety valve.

On the return line assemble at least another pressure safety valve.

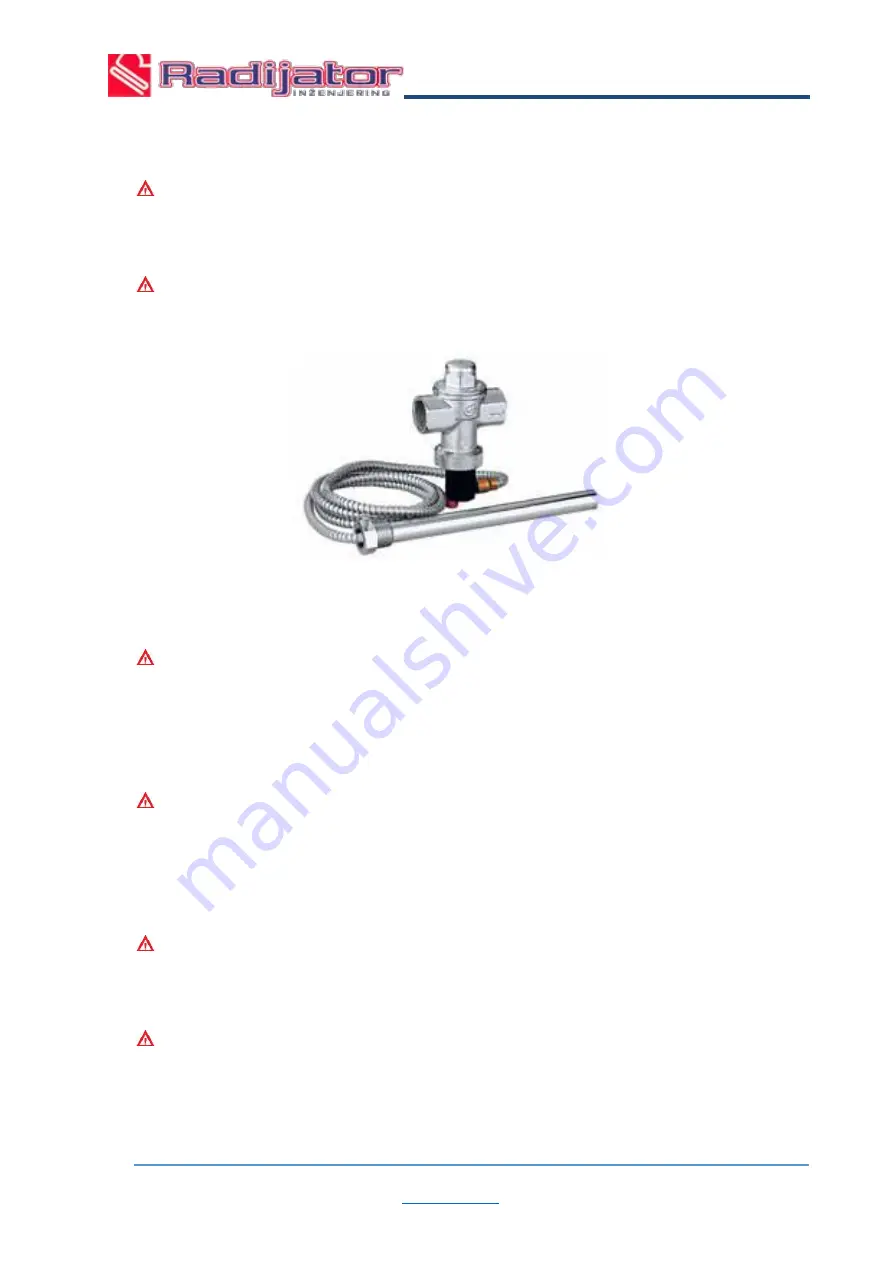

4.3. The valve of thermal safety by swelling (Figure 7)

Figure 7.

This safety element also has a role of a limitator of temperature. Below it will be marked with

the abbreviation VTO.

In some extremely dangerous situations in the transformation of water into vapor is

such that the pressure safety valves are not sufficient to ensure the safety of the

hydraulic system. For this reason, the installation of VTO is mandatory. Depending on

the regulations of the countries in which the boiler is assembled, it is necessary to install

the VTO only for the determined higher powers or for each power of a boiler it is the

obligatory to install the VTO.

Place the installation is shown in the Assembly diagram of boiler onto the installation

in

Figure 8

. The boiler is supplied with a copper coil so it is necessary to use the VTO

with the exchanger, as shown in

Figure 8

. Cold sanitary water is brought to the VTO.

When the VTO-probe has the information that the temperature is over 95 degrees the

VTO is opened and water flows through copper coil. After some time the temperature

of water in boiler returns to its normal state.

One connection of coil is used for VTO and the other for draining of water that has

passed through the coil. The choice of either connection; for VTO or for the discharge

is irrelevant. It is necessary to follow the installation instructions provided by the

manufacturer of the VTO.

Be sure to check up, in certain periods of time, the functioning of the VTO.

As stated above one end of the VTO is for the mounting on the exchanger of the boiler, and the

other is supplied with cold water under pressure. It is particularly important that the water flow

is unobstructed even when the electricity is switched off.