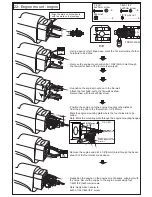

26- Linkages

Elevator push rod

Elevator push rod

Tail wheel push rod

Rudder push rod

Throttle push rod

................2

....................3

2mm

Connector

Elev. servo

Rudder servo

Thrott. servo

BOTTOM VIEW

X

Elevator pushrod

or rudder pusshrod

D=5/64”(2mm)

Tail wheel pushrod

D=.050”(1.2mm)

3mm set Screw

2 mm

Elevator pushrod

ELEVATOR / RUDDER SERVO

X

3mm set Screw

2 mm

THROTTLE SERVO

throttle pushrod

D=.050”(1.2mm)

2.5x10mm

27- Cowling installation

1~2mm

Board or

transparent

plastic

Adhesive

tape

1-Attach the board or transparent plastic on the side of

the fuselage with the adhesive tape as show.

2-Using a pencil or felt tipped pen trace around the engine

head where it meet the cowl. Cut the opening the board

or transparent plastic for the engine head as marked before.

3-Remove the engine and insert the cowl on to the fuselage

so the distance from the fire wall to the front of the cowl is

4-59/64”(125mm). Trace around inside the hole on the board

or transparent plastic with a pencil.

4-Remove the cowl from the fuselage and carefully cut the

opening for the engine head as marked above. Do the same

way with the hole for needle-valve.

5-Again. Insert the cowl on to the fuselage and secure it in

place with five 2.5x10mm self tapping screws.

125mm

Ruler

Cut the opening

Cut the opening

1.5mm

1/16”

1.5mm

1/16”

2.5x10mm self

tapping screw

3/32x25/64” self tapping screw

.................4

1/16”