28

Adjust the linkage or the

END POINT

? It is nearly always best to adjust your linkages to get as close as possible prior to

utilizing

END POINT

. The higher the

END POINT

setting, the better position accuracy and the more servo power available

at nearly any position (except if using digital servos). Higher

END POINT

values also mean longer travel time to reach the

desired position, as you are utilizing more of the servo's total travel. (For example, using 50%

END POINT

would give you

only half the steps of servo travel, meaning every click of trim has twice the effect and the servo gets there in half the

time).

• end point (and moving the linkage) = torque, accuracy, but transit time to get there.

• end point (instead of adjusting linkages) = travel time, but torque, accuracy.

GOAL of EXAMPLE:

STEPS:

INPUTS:

Decrease the flap servo throw in the

u p w a r d d i r e c t i o n t o 5 % t o a l l o w

WULPPLQJRIOHYHOÀLJKWRQO\DQGGRZQ

travel to 85% to prevent binding.

Open

END POINT

function.

for 1 second.

(If

ADVANCE

,

again.)

C

to

END POINT

.

Choose proper channel and move stick

or knob in direction you want to adjust

DQGVHWVHUYRWKURZ([ÀDSXS

C

to

FLAP

.

ÀDSFRQWURO>GHIDXOWLV

VR(A)

].

to

5%

.*

VR(A)

.

to

85%

.

Close.

Where next?

Go to

SERVO

GLVSOD\WRFRQ¿UPGHVLUHGHQGUHVXOWVHHS

0RYHDX[LOLDU\FKDQQHOVWRGLIIHUHQWGLDOVVZLWFKHVVOLGHUVVHHS

Set up

IDLE-DOWN

and

THR-CUT

WRVORZFXWWKHHQJLQHVHHS

6HWXSGXDOWULSOHUDWHVDQGH[SRQHQWLDO

D/R

,

EXP

): see p. 30.

6HWXSÀLJKWWLPHUVVHHS

Set up trainer functions: see p. 34.

Set up twin aileron servos: see p. 39.

Set up twin elevator servos: see p. 44.

Engine idle management:

IDLE-DOWN

and

THR-CUT

: functions which work with the digital

THROTTLE TRIM

to provide

a simple, consistent means of engine operation. No more fussing with getting trim in just the right spot for landings or take

offs! For additional engine adjustments, see

THROTTLE-NEEDLE

(p. 50) and

THROTTLE DELAY

(p. 51).

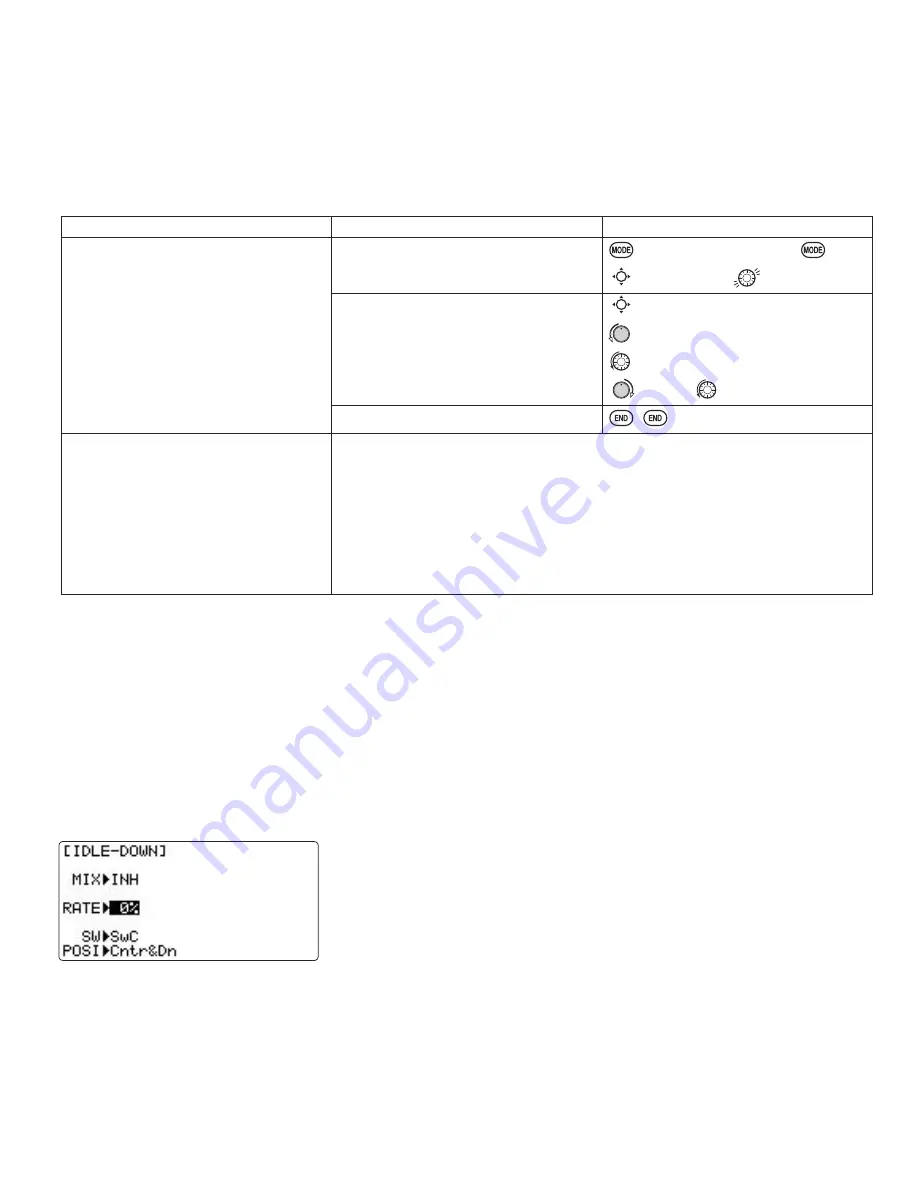

IDLE-DOWN

(

ACRO

only): lowers the engine idle for: sitting on the runway prior to take off, stalls and spins, and landings.

7KHQRUPDOLGOHVHWWLQJLVDOLWWOHKLJKHUIRUHDVLHUVWDUWVDQGVDIHÀLJKWVZLWKOHVVULVNRIGHDGVWLFNV

Important note: The

IDLE-DOWN

function is not normally used when starting the

engine, and its accidental operation may keep your engine from starting. The

AT10 w

arns that

IDLE-DOWN

is on when the transmitter is turned on. Be sure to

turn off the function, or override the warning by pressing CURSOR lever if you

intended the function to be on.

7KLVPD\EHDVVLJQHGWRDQ\VZLWFKSRVLWLRQ6RPHPRGHOHUVDFFLGHQWDOO\DVVLJQ

IDLE-DOWN

to one side of a switch

and

THR-CUT

to the other. There is no “normal” setting to start the engine. By default

IDLE-DOWN

is set to

SWITCH C

center and down. This works well with

THR-CUT

also on

SWITCH C

GRZQ7KH6:,7&+XSLVQRUPDOÀLJKWVWDUWLQJ

FHQWHUIRUVORZHUPDQHXYHUVODQGLQJDQGGRZQWRFXWWKHHQJLQH,I\RXDVVLJQ

IDLE-DOWN

or

THR-CUT

to the spring-

loaded

TRAINER

SWITCH F

, then use the trainer function, you may risk loss of throttle control

or deadstick for your student.

*You can reset to the initial values by pressing the

DIAL

for one second.

28.

37.

33.