8

than 50cm or high current draw servos are being used ,use heavy servo extensions.

• Receiver Vibration and Waterproofing: the receiver contains precision electronic part.Be sure to avoid

vibration,shock,and temperature extremes.For protection, wrap the receiver in foam rubber or other

vibration-absorbing materials. It is also a good idea to waterproof the receiver by placing it in a plastic bag

and securing the open end of the bag with a rubber band before wrapping it with foam rubber. If you

accidentally get moisture or fuel inside the receiver,you may experience intermittent operation or a crash. If

in doubt, please contact Radiolink aftersales or distributors for service.

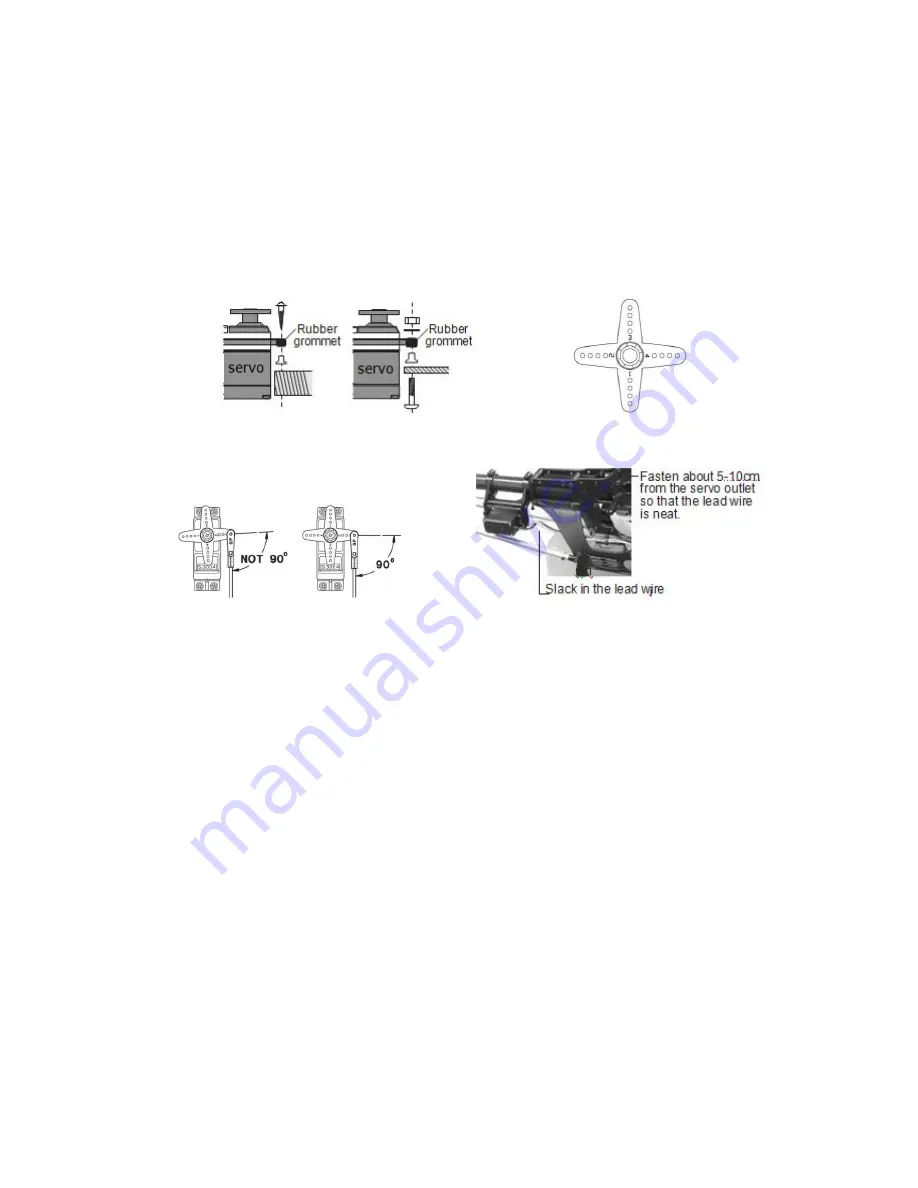

• Always mount the servos with the supplied rubber grommets.Don’t over tighten the screws.No part of the

servo casing should contact the mounting rails,servo tray or any part of structure.Otherwise vibration will be

transmitted to the servo causing damage of servo.Note the small numbers (1,2,3,4) molded into each arm on

the servo arms.The number indicate how many degrees each arm is ‘off’ from 90 degrees to correct for

minute manufacturing deviations from servo to servo.

• To center the servos, connect them to receiver and turn on the transmitter and receiver.Center the trims

on the transmitter,then find the arm that will be perpendicular to the pushrod when placed on the servo.

• After the servos are intalled,operate each servo over its full travel and check that the pushords and

servo arms don’t bind or contact each other.Also make sure the controls do not require excess force to

operate. If there is an objectionable buzzing sound coming from a servo, there is probably too much

resistance in the control.Find and correct the problem.Even is there is no servo damage,excess battery drain

will result.

• Use the mouting plate from the receiver on/off switch as a template for the cutout and screw

holes,mount the switch on the side of the fuselage opposite the engine exhaust, and where it won’t be

inadvertently turned on or off during handling or storage.Be certain the switch moves without restriction and

‘snaps’from ON to OFF, and that the cutout allows full motion of the switch in both directions.

• When intall the switch harness to the helicopter,please use the switch cover.Generally sandwich the

frame between the switch and switch cover and securely tighten the screws,Different models might require

different installations.If so ,please follow the model’s instruction manual

.

• To prevent the servo lead wires from being broken by vibration during flight,provide a slight amount

of slack or extra so that the wire sticks out slightly and fasten it at suitablr points.In addition,periodically

check the wire during daily maintenance.