19

4

1

/

2

" Angle Grinder - Owner's Manual

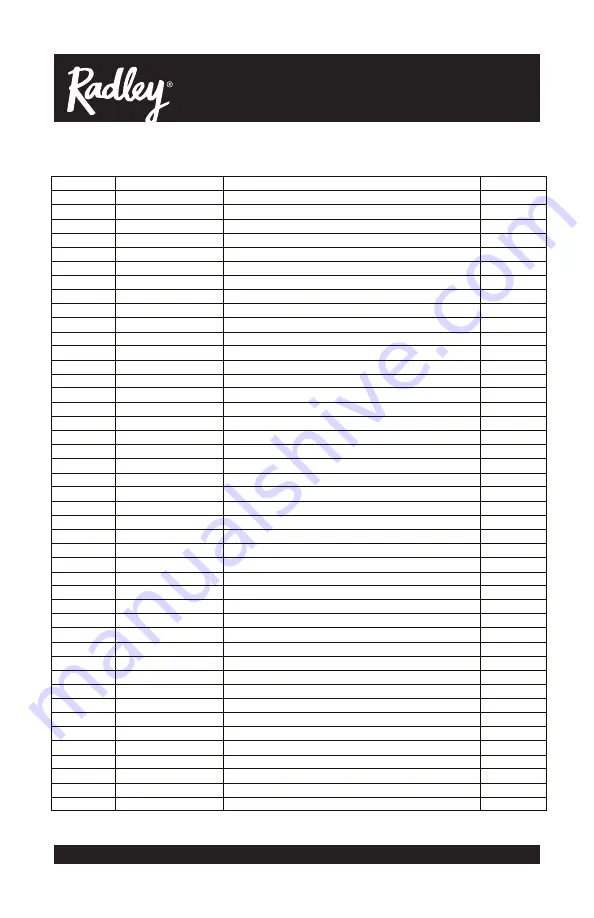

PARTS

Key #

Part #

Part Name

Quantity

39

1249-998-39

Screw ST4x14

1

40

1249-998-40

Power Cord Clamp

1

41

1249-998-41

Y connector

1

42

1249-998-42

Power cord Sleeve

1

43

1249-998-43

Power cord

1

44

1249-998-44

Switch Extension

1

45

1249-998-45

Rear Housing

1

46

1249-998-46

Wrench

1

35

1249-998-35

Carbon Brush

2

36

1249-998-36

Motor Housing

1

37

1249-998-37

Power Switch

1

38

1249-998-38

Internal Switch

1