Page 13 of 22

IN052 Rev. K 0613

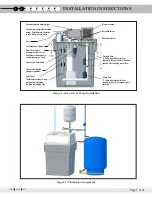

2.5. Vent Line Installation

Use only 2”, 3” or 4” Schedule 40 PVC or equivalent pipe

for vent line. Follow all applicable AARST, EPA, and/or

State Standards for Radon or VOC venting.

1.

Connect vent line to 2” socket elbow on the rear of the

system (figure 9). Use PVC cement in a fashion that ensures

no leakage will occur. Note: A rubber coupling permitting

disconnection of the system from the vent line for future

maintenance is provided beneath the cover.

2.

The vent line must be mounted in a fashion that allows the

system to exhaust above the level of the roof (Figure 10).

3.

The vent must be pitched back towards the system to ensure

that any condensation runs back into the unit. If an optional

inline auxiliary fan is used, recommendations regarding

pipe pitch in the fan installation instructions must be strictly

adhered to.

4.

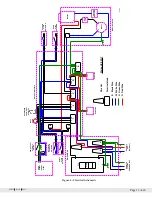

If an optional auxiliary fan is used then the fan must be

wired to the system electrical box, connections as shown in

the Electrical Schematic (Figure 8). This will ensure that the

fan operates only when required by the system. The “red”

lead is the live feed from the Aeration System to the Fan.

Warning: Do Not connect any of the Fan Leads to a separate power

source. This will cause the Aeration System to Malfunction

5.

Install weather cap on top of the vent line. This cap should

not restrict air flow and must prevent rain, snow and other

contaminants from entering the vent line.

Failure to install a proper vent line may cause

contamination of the water, outgassing of

contaminants into the building, limit system

performance and/or cause the system to

overflow.

NOTE: The Manufacturer has found that vent lines less than 250

equivalent linear feet do not cause a decrease in contaminant

removal percentages. 90° Bend = 15 Equiv. Linear Ft ; 45° Bend =

7 Equiv. Linear Ft. An inline auxiliary fan is recommended if the

vent line exceeds 250 equivalent linear feet.

Figure 9 - Vent Line Connection

Figure 10 - Vent Line Installation

INSTALLATION INSTRUCTIONS

1

2

Vent

connection