Page 4 of 8

IN006 Rev G

1.5

CONDENSATION & DRAINAGE

Condensation is formed in the piping of a mitigation system when the air in the

piping is chilled below its dew point. This can occur at points where the system

piping goes through unheated space such as an attic, garage or outside. The

system design must provide a means for water to drain back to a slab hole to

remove the condensation.

For GP500 piping, the following table provides the minimum recommended pipe

diameter and pitch under several system conditions.

Pipe

Diam.

Minimum Rise per Foot of Run*

@ 25 CFM

@ 50 CFM

@ 100 CFM

4"

1/8 "

1/4 "

3/8 "

3"

1/4 "

3/8 "

1 1/2 "

*Typical GP500 operational flow rate is 25 - 90 CFM.

(For more precision, determine flow rate by using the

chart in the addendum.)

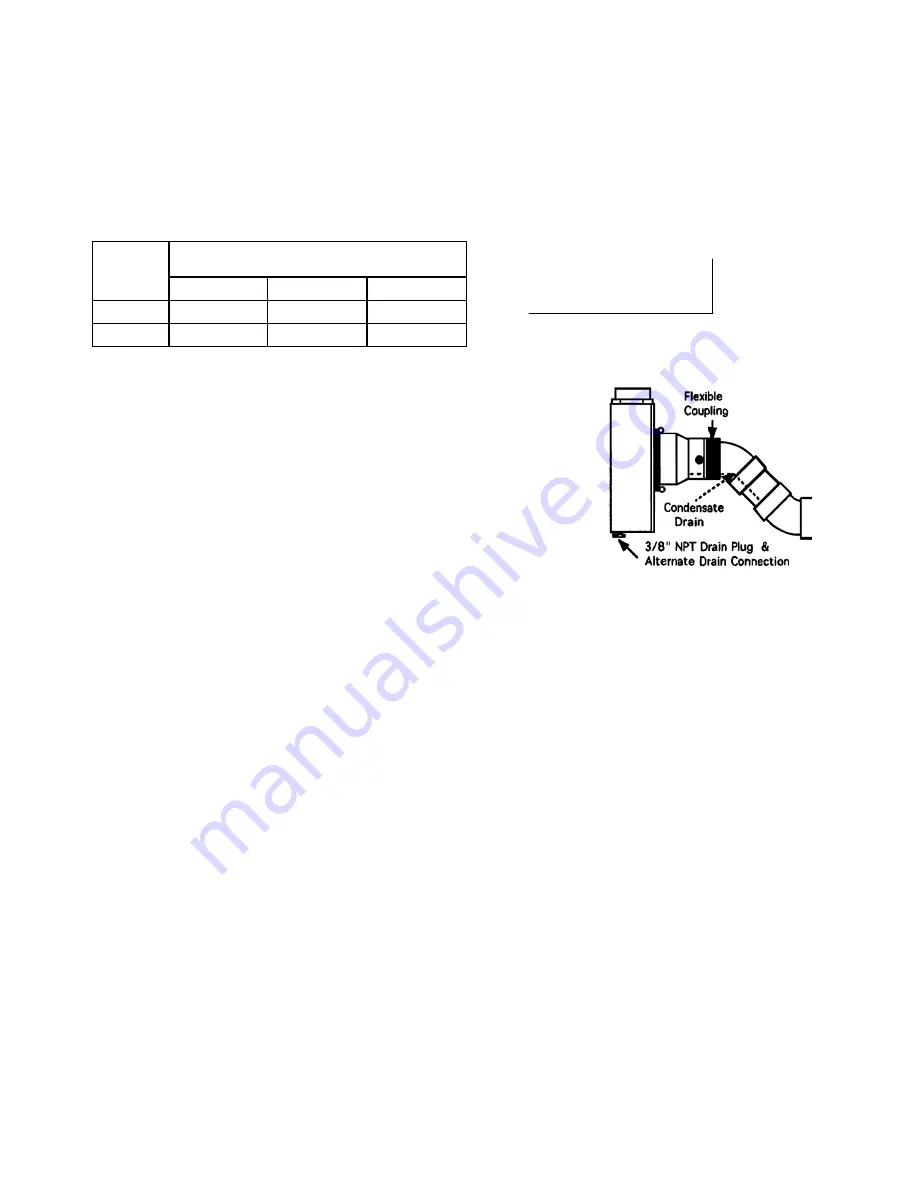

The GP500 incorporates a unique condensation drain

system which actively pumps water back to the inlet

piping for drainage to a slab hole. It is required

that the system piping provide a drop-off immediately

at the inlet of the unit, as shown in Figure 1, to

prevent reintrainment of condensation. If this is not

possible the condensate drain tube may be extended to

the point of drop off by slipping 5/16" ID tubing

(available from RadonAway) over the drain tube.

Figure 1

An alternative condensation drain may be provided using the 3/8" NPT fitting on

the bottom of the unit. The alternative drain system must account for Radon

leakage as the drain is under positive pressure. If the unit is installed and

electrical power is removed for extended periods of time the drain plug should be

removed to allow water to drain from the unit.

IMPORTANT: Do not overtighten drain plug! Do not use a wrench or tighten beyond

finger tight. Apply sealant to threads if required.

1.6 "SYSTEM ON" INDICATOR

A U-Tube manometer or a vacuum alarm is recommended as a "System On" Indicator

for affirmation of system operation.

1.7 SLAB COVERAGE

The GP500 can provide coverage up to 1000+ sq. ft. per slab penetration. This

will, of course, depend on the sub-slab material in any particular installation

and the diagnostic results. In general, the tighter the sub-slab material, the

smaller the area covered per penetration. Additional suction points can be added

as required. It is recommended that a small pit (5 to 10 gallons in size) be

created below the slab at each suction hole.

Run

Rise

Summary of Contents for GP500

Page 1: ...Page 1 of 8 IN006 Rev G ...