ADAPTER INSTALLATION PROCESS

OM 0467QH-A

[39]

JIC

T

HREAD

I

DENTIFICATION

&

T

ORQUE

JIC flare fittings seal with metal to metal contact between the flared nose of the fitting and the flared

tube face in the female connection.

The minimum torque values listed are to provide a benchmark that give optimum results for leak free

connections. Actual torque values should be based on individual application.

NOTE

: Do not apply thread sealant (Teflon tape) on the JIC threads.

Leaks can result from vibration, thermal cycling and from loads being supported by the connection (i.e.

using the fitting in the connection to support mechanical loads).

IMPORTANT:

Use the lowest torque value from the chart when wet torquing.

R

ECOMMENDED

A

SSEMBLY

STEP 1:

Inspect for possible contamination or

damage from shipping or handling. Sealing

surface should be smooth.

STEP 2:

Lubricate the threads and the entire

surface of the cone with hydraulic fluid or a light

lubricant.

STEP 3:

Align mating components for hand

connection and turn flare nut until sealing

surfaces make full contact.

STEP 4:

Torque nut to the values shown in the

above table.

STEP 5:

When torquing nut onto a straight flared

fitting, it may be necessary to also place a wrench

on the flared fitting wrench pad to prevent it from

turning during assembly.

A

LTERNATE

A

SSEMBLY

M

ETHOD

STEP 1:

Inspect for possible contamination or

damage from shipping or handling. Sealing

surface should be smooth.

STEP 2:

Lubricate the threads and the entire

surface of the cone with hydraulic fluid or a light

lubricant.

STEP 3:

Align mating components for hand

connection and turn flare nut until sealing

surfaces make full contact.

STEP 4:

Lightly wrench tighten the nut until

there is resistance.

STEP 5:

Place a wrench on wrench pad next to

nut as near the 6 o'clock position as possible.

STEP 6:

Place second wrench on nut as near

the 3 o'clock position as possible.

STEP 7:

Turn nut clockwise to no less than the

4 o'clock position, but no more than the 6

o'clock position. Required rotation generally

decreases as size increases.

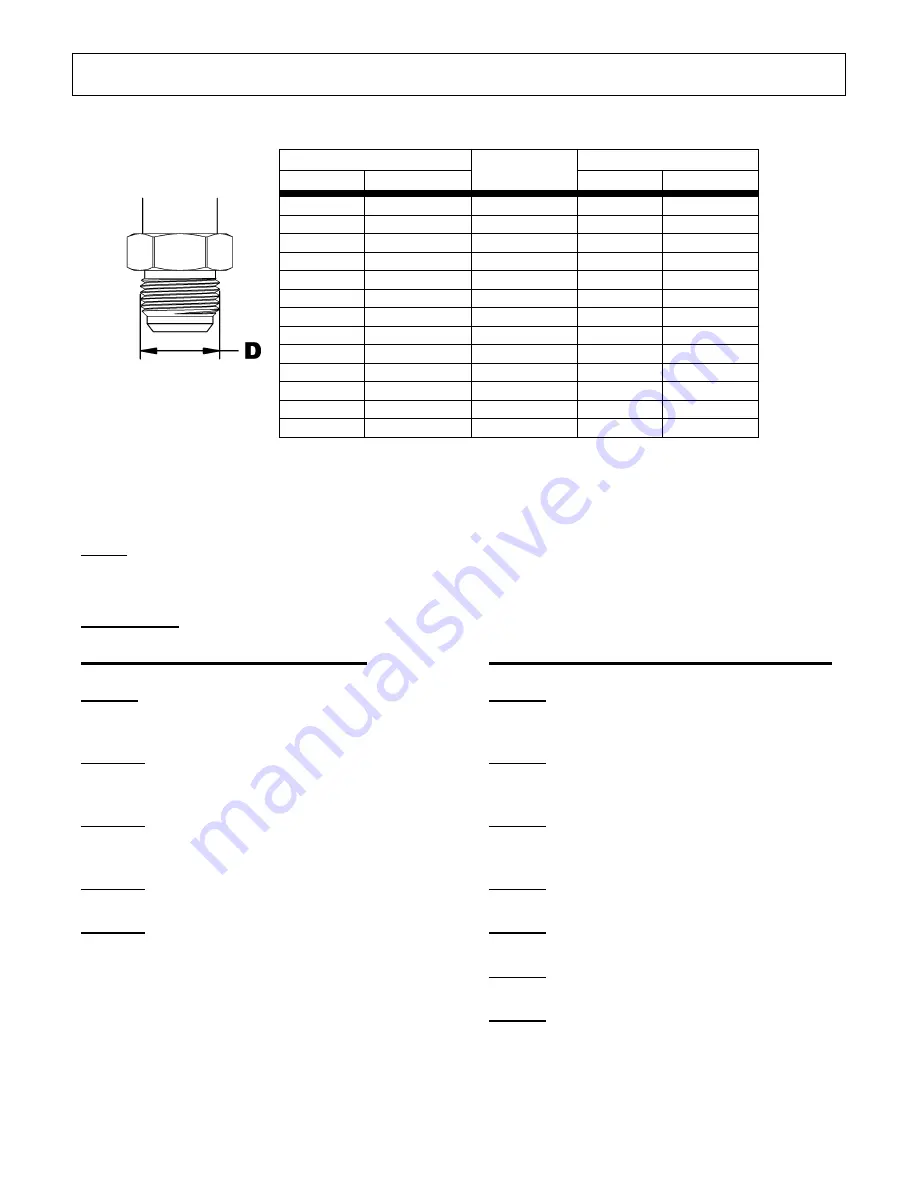

D

Identification

TORQUE

in mm

of

adapter

lbs-ft

N-m

- -

5/16

JIC

6-7

8-10

- -

3/8

JIC

6-9

8-12

0.433 11

7/16

JIC

9-12

12-16

0.496 12.6

1/2

JIC

14-15

19-21

0.559 14.2

9/16

JIC

18-20

24-27

0.740 18.8

3/4

JIC

27-39

37-53

0.870 22.1

7/8

JIC

36-63

49-85

1.055

26.8

1 1/16 JIC

65-88

88-119

1.185

30.1

1 3/16 JIC

75-103

102-140

1.307

33.2

1 5/16 JIC

85-113

115-153

1.618

41.1

1 5/8 JIC

115-133

156-180

1.870

47.5

1 7/8 JIC

125-167

169-226

2.492

63.3

2 1/2 JIC

190-258

258-350

Summary of Contents for LS Tractor LW3150

Page 2: ......

Page 9: ...GENERAL SAFETY INFORMATION OM 0467QH A 7...

Page 10: ...GENERAL SAFETY INFORMATION OM 0467QH A 8 1 Safety stand 2 Secure point for safety stand...

Page 31: ...MAINTENANCE OM 0467QH A 29 LUBRICATION TWICE A YEAR TWICE A YEAR...

Page 35: ...PARTS OM 0467QH A 33 4 POINT HITCH AND SUBFRAME...

Page 43: ......