- 17 -

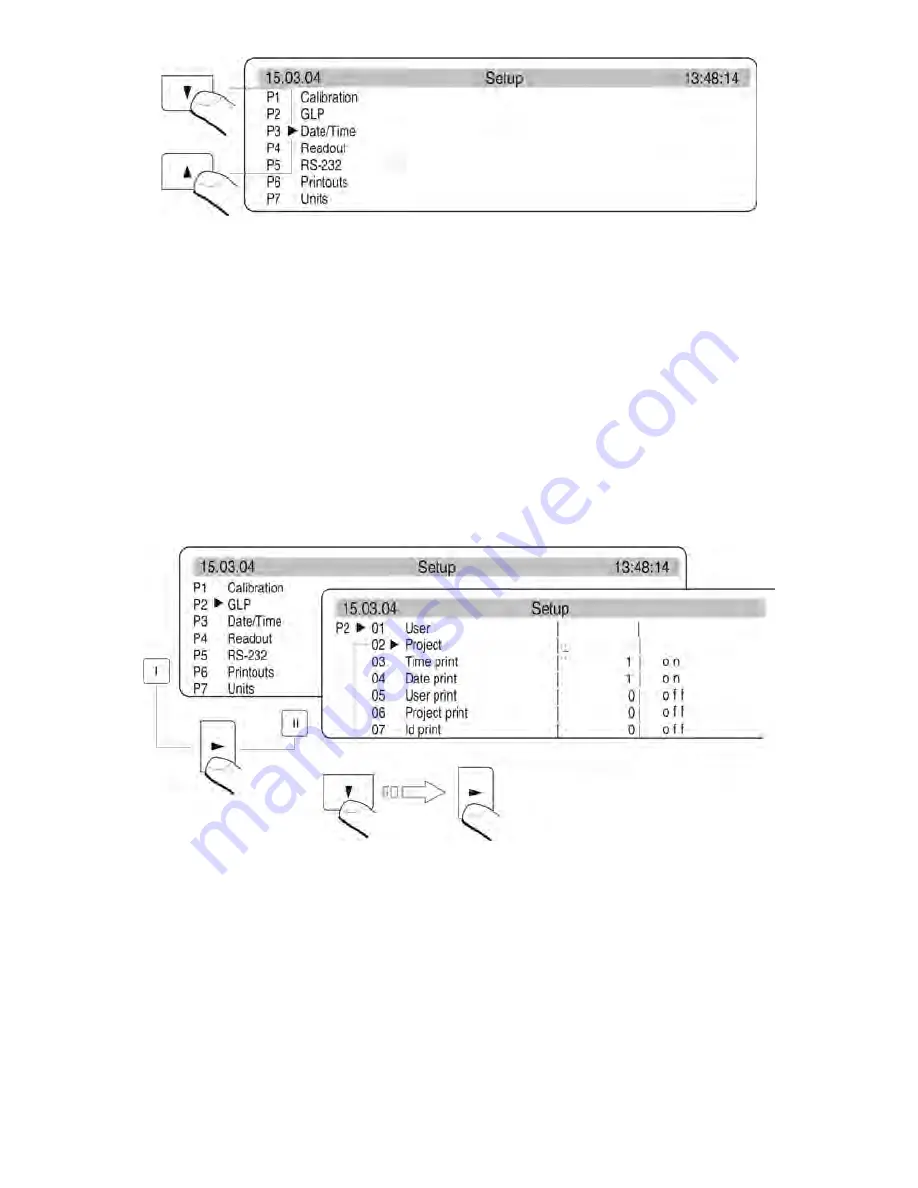

Fig. 7. Balance main menu – submenu selection

In order to edit a submenu, press

RIGHT ARROW

key, which opens the content of

selected submenu. When inside the submenu structure, the user can select an option to be

edited (modified) by placing the cursor next to submenu name (use up and down

navigating arrows). When the cursor is placed next to desired option press

RIGHT

ARROW

key to enter submenu settings.

Balance reactions for above procedure:

-

A specific process (e.g. balance adjustment) which is carried out in a submenu

described as a function;

-

Editing an attribute of a submenu (flickering digit of a submenu setting enables

changing parameter value of entering a sequence of characters)

Fig. 8. Balance submenu – selection buttons