31

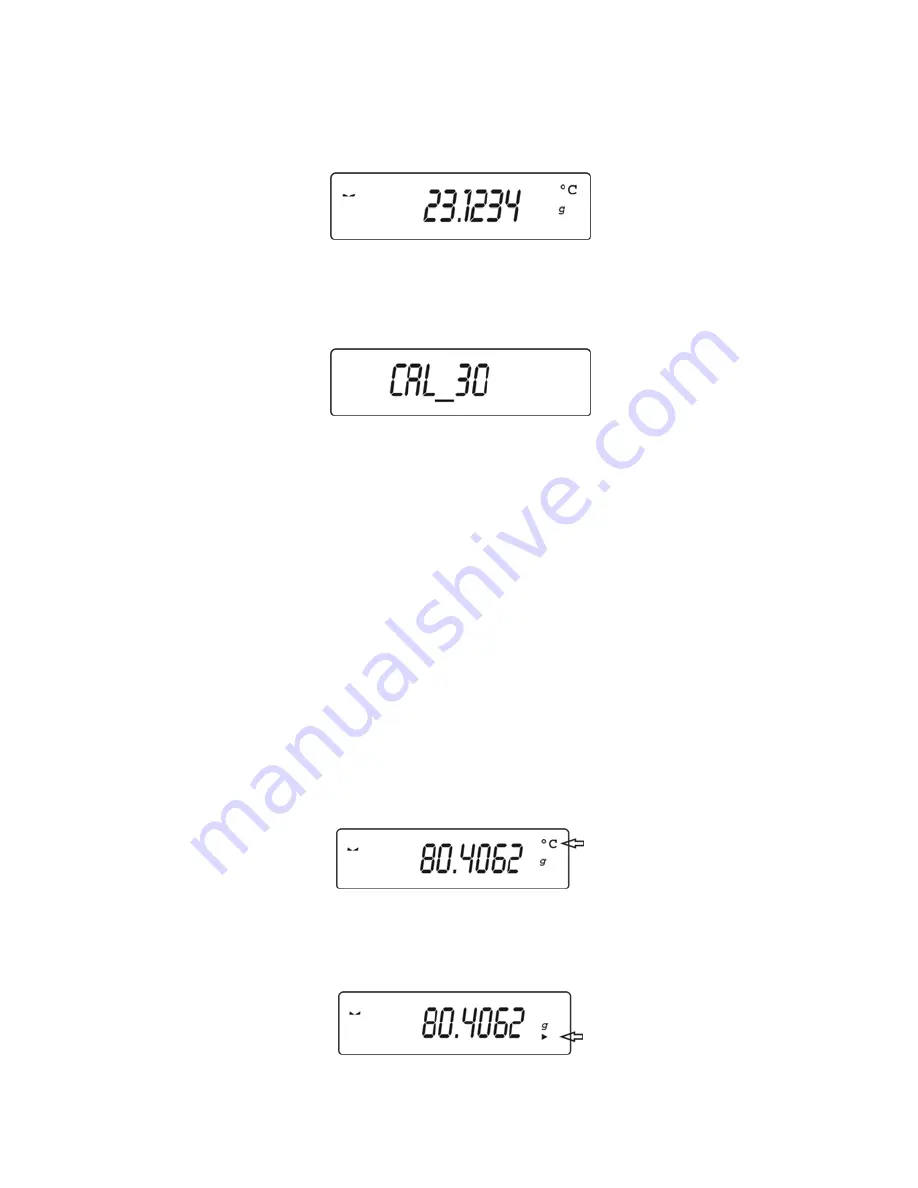

Cycle of automatic calibration proceeds as follows:

-

balance software detects necessity of calibration and signalizes it by marker of

Celsius degree or by black marker

-

from this moment time of 5 minutes is counted in which weighings can be

performed

-

when this time elapses display indicates CAL_30 message and starts count

down 30..29..28 do 0 (indicated value is the counter)

-

user has 30 seconds to make a decision:

if calibration is to be performed, does not take any actions

if one wants to finish measurements presses

TARE

key, after its pressing

balance returns to weighing showing previous result of weighing (possibility

of finishing series of measurements) in 5 minutes balance will indicate

CAL_30 message again

-

process of calibration can be postponed frequently, but fact that long postponing

of calibration can be cause of bigger error during weighing should be noticed.

These errors are effect of changes of temperatures and as consequence

changes of balance sensitivity.

Automatic system includes 3 possibilities:

-

calibration with regard to changes of temperature

balance is provided with precise system of controlling temperature

changes, temperature of calibration is registered every time, next is started

if temperature of surrounding changes 0,8

o

C

-

calibration with regard to passage of time

user can declare 4 spaces of time that makes criterion for calibration,

following option are accessible: calibration every 1 - 12 hours.

Summary of Contents for AS series

Page 2: ...2 MARCH 2009...