- 54 -

After weighing process completion, the measurement result is locked and automatically printed.

In order to finish the measurement, press

button.

The program automatically returns to the main window of Animal weighing mode.

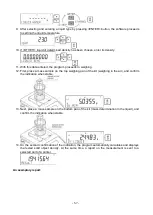

11.7.3. Running the Process Automatically – Means of Operation

To start the process of weighing automatically, enter the mode settings, select an <AUTOSTART>

parameter and set <YES> value, follow description form the previous paragraph. Additionally set

parameters <AVERAGING TIME> and <THRESHOLD>.

In order to carry out the measurement in a container (TARE) for this mode, select the option <ENTER

TARE>, for the option overview to be found in weighing mode options description.

To start the process (after setting the options), enter the weight of the container, then put the

container on the pan and place the object that is being weighed in the container. The balance

automatically begins the process of measurement after exceeding the set mass threshold.

After weighing process completion, the measurement result is locked and automatically printed.

In order to finish the measurement, press

button.

The program automatically returns to the main window of Animal Weighing mode.

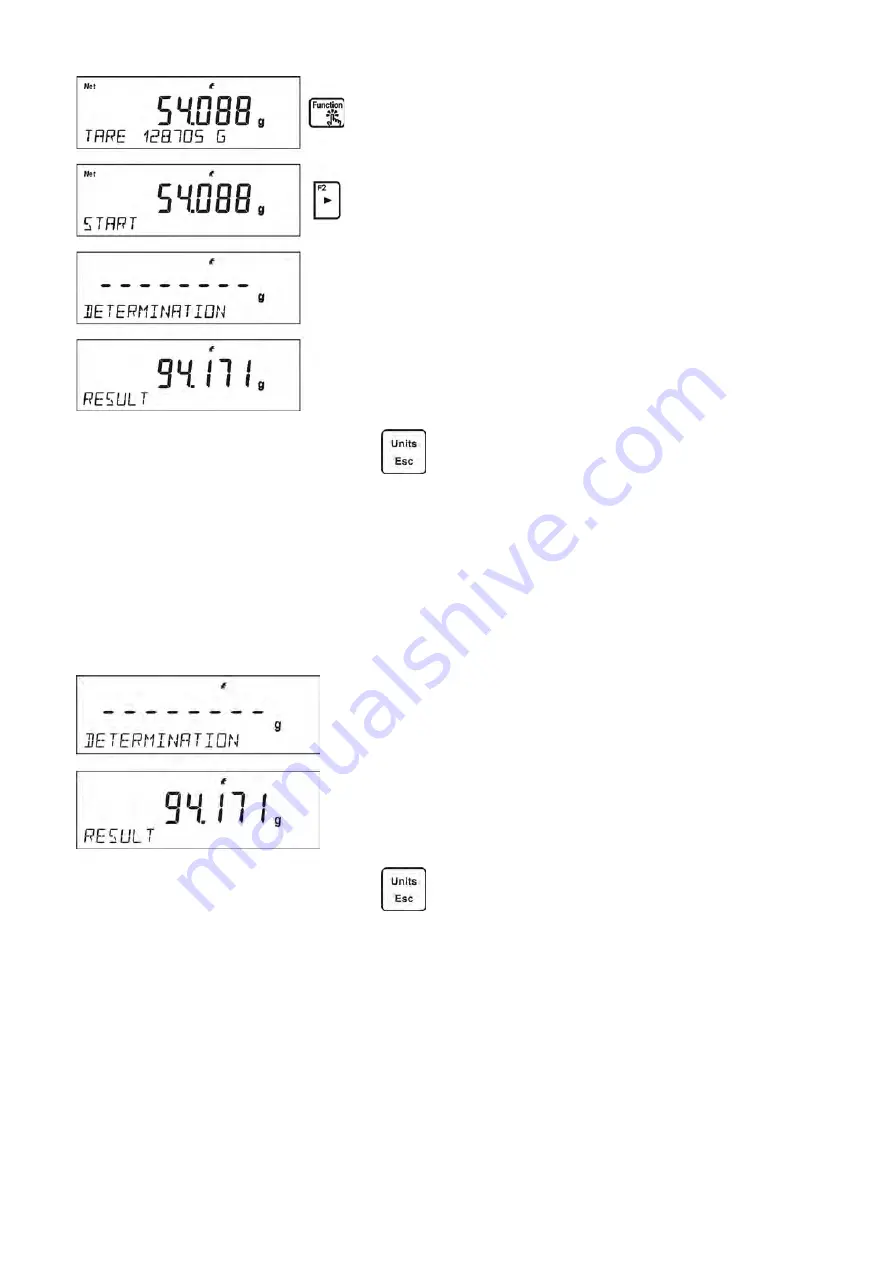

11.8. DENSITY OF SOLIDS

Solids Density

is a working mode enabling determination of density of a representative sample

material.

In order to operate this mode, an optional density kit (supplementary equipment), appropriate to

a model of used balance, is required. Prior to installing the kit it is necessary to remove the weighing

pan and a draft shield. In the place of the weighing pan assemble the weighing pan stand (1) and

place beaker’s basis (10) on it.

Summary of Contents for PS 200/2000 R2

Page 95: ...95...