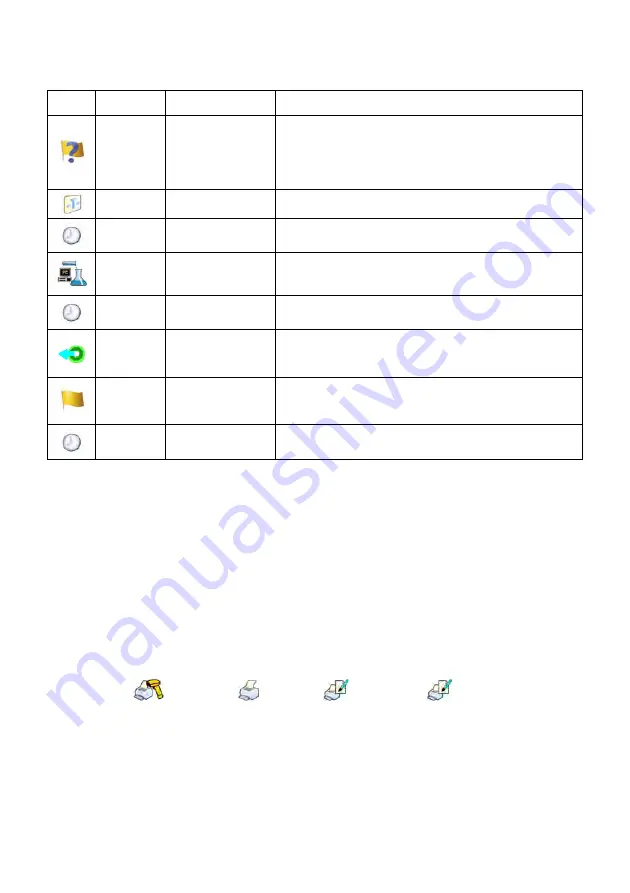

Platform 2:

Icon Step

Value

Description

1. [CF]

Flags

condition

Signal flag 1 – „1”

Checking condition, whether signal flag 1 is set to

value “1” – i.e. checking whether desired part of the

process has been already realized on the weighing

platform no. 1. If Yes, then dosing process on the

weighing platform no. 2 shall start.

2. [T]

Tare

Tare

Tarring the weighing platform no. 2

3. [TI]

Delay

[5s] Open valve

Water

Pending for opening main valve of the container with

“Water”

4. [DA]

Automatic

batching

2 kg [Water]

Automatic dosing of ingredient “Water” to obtain 2 kg

mass in single-step dosing mode – Output 6 controls

the dosing valve (set for Water in Products database)

6. [TI]

Delay

[5s] Close valve

Water

Pending for closing the main valve of the container

“Water”

7. [O]

Outputs

Output 12 – „1”

Output 12 takes high status (“1”) – signal confirming

carrying out the dosing process on the weighing

platform no. 2 is lit up

8. [F] Set

flags

Signal flag 1 – „1”

Signal flag 2 – „1”

Setting the characteristic point of the process, which is

a condition for carrying out part of the process on the

weighing platform no. 1

8. [TI]

Delay

[10s] Dosing

completed

Displaying a text message on the terminal confirming

completion of dosing process

An instance of mixed dosing (manual and automatic) has been extended by

signalling its corresponding phases to present the possibilities of the working

mode

<Dosing>

.

28.7. Reporting of completed dosing processes

On completing each dosing process, the terminal automatically generates

a report on that process.

Caution:

Submenu: “

Devices /

Printer /

Printouts /

Dosing

report printout template” enables optional modifying of the report

template (see ch. 16.2.3 of this user manual).

140