Raider 40 HP

Appendix Alfa

Owner’s Manual

Pre Operations Checks

57

P

RE

O

PERATIONS

C

HECKLIST

Motor Serial

Number:

Motor Hours:

Date of

Operation:

Before placing the Raider Outboard 40 into service and or starting the engine, complete the checks listed in the

Preoperational Checklist. The Preoperational Checklist is designed to ensure that the motor and all systems are

in proper working order to support motor operation, and to ensure safe and efficient boat operation.

NOTE:

The Preoperational Checklist may be modified to meet operational commitments. Not all steps may be

required every time prior to start.

NOTE:

This list of preoperational checks is not inclusive.

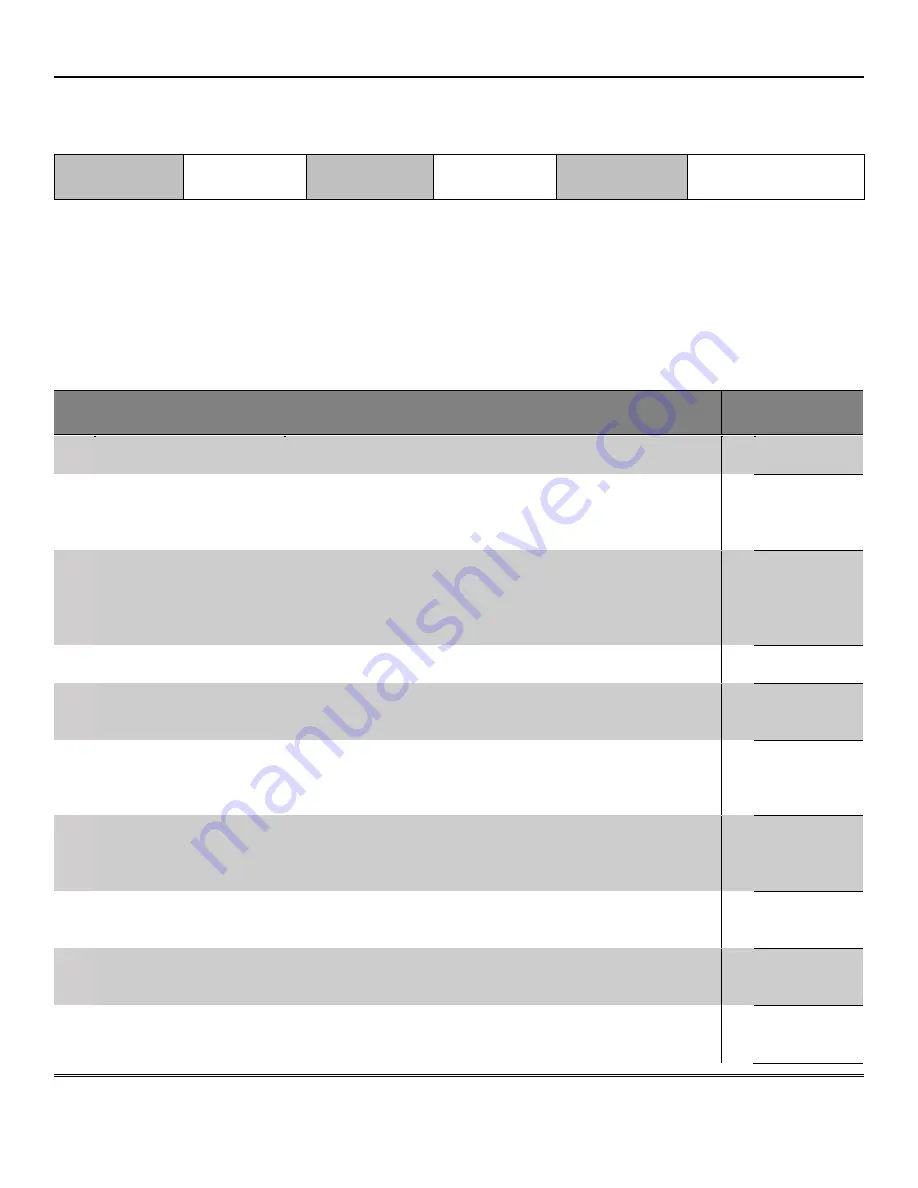

General Checks

Completed

(initial)

a.

Exterior

•

Inspect Cowling, Engine Pan, Midsection, and Lower Unit for

cracks, defects, or damage.

a.

b.

Zinc Anodes

•

Stern Brackett Anode. Replace if damaged or reduced in size by

more than 40%.

•

Trim Tab Anode. Replace if damaged or reduced in size by more

than 40%.

b.

c.

Control Panel

•

Inspect the Start and Stop controls.

•

Verify the Lock Plate and Lanyard are installed.

•

Inspect for damage due to corrosion, lack of maintenance, or

abuse. Loose ball joints, locknuts, bent link rods, loose rod

snaps.

c.

d.

Cable Lanyard

•

Verify the Cable Lanyard is securely attached to the motor and

maybe securely attached to craft Transom.

d.

e.

Shift Lever Mechanism and

Shift Lever Stopper

•

Inspect for damage due to corrosion, lack of maintenance, or

abuse. Loose ball joints, locknuts, bent link rods, loose rod

snaps.

e.

f.

Throttle Linkage

•

Inspect for damage due to corrosion, lack of maintenance, or

abuse. Loose ball joints, locknuts, bent link rods, loose rod

snaps.

•

Lubricate with low temperature lithium grease.

f.

g.

Throttle Advancer Arm and

Rod, Throttle Mechanism,

Handel, and Grip.

•

Inspect for damage due to corrosion, lack of maintenance, or

abuse. Loose ball joints, locknuts, bent link rods, loose rod

snaps.

•

Lubricate with Friction Surface Marine Grease.

g.

h.

Tilt Stopper, Bracket Bolt,

Bracket Shaft, Clamp Screw,

and Reverse Lock.

•

Inspect for damage due to corrosion, lack of maintenance, or

abuse.

•

Lubricate with Friction Surface Marine Grease.

h.

i.

Hook Lever Mechanism

(cowling)

•

Inspect for damage due to corrosion, lack of maintenance, or

abuse.

•

Lubricate with Friction Surface Marine Grease.

i.

j.

Recoil Starter

•

Inspect for damage due to corrosion, lack of maintenance, or

abuse.

•

Lubricate with Friction Surface Marine Grease.

j.

Summary of Contents for Raider 40 HP

Page 1: ...i ...

Page 2: ...ii This page intentionally left blank ...

Page 65: ...56 APPENDICES ...

Page 69: ...60 Notes and Discrepancies ...

Page 72: ...This page intentionally left blank ...

Page 73: ......