16

www.raider.bg

design:

1. Damage to lungs if an effective dust mask is not worn.

2. Damage to hearing if effective hearing protection is not worn.

3. Damages to health resulting from vibration emission if the power tool is being used over longer

period of time or not adequately managed and properly maintained.

WARNING! This power tool produces an electromagnetic field during operation. This field may

under some circumstances interfere with active or passive medical implants. To reduce the risk of

serious or fatal injury, we recommend persons with medical implants to consult their physician and

the medical implant manufacturer before operating this machine.

INTEND USE

Coating Materials Suitable for Use

Water- and solvent-based paints, finishes, primers, 2-component paints, clear finishes, automotive

finishes, staining sealers and wood sealer-preservatives.

Coating Materials Not Suitable for Use

Wall paints (emulsion paints) etc., alkali and acidic paints.

Wear hearing protection while operating the power tool

.

The declared vibration total value has been measured in accordance with a standard test

method and may be used for comparing one tool with another.

The declared vibration total value may also be used in a preliminary assessment of exposure.

WARNING

The vibration emission during actual use of the power tool can differ from the declared total value

depending on the ways in which the tool is used.

There is the need to identify safety measures to protect the operator that are based on an

estimation of exposure in the actual conditions of use (taking account of all parts of the operating

cycle such as the times when the tool is switched off and when it is running idle in addition to the

trigger time).

U

SE

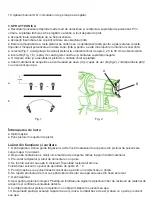

1. PREPARING THE COATING MATERIAL

The paints usually need to be diluted for use with the spray gun. Since information on sprayable

dilutions is seldom given on the material tin, you can use the guidelines in the viscosity table on the

following page (viscosity = consistency of the coating material).

Measuring the Viscosity

1. Stir the coating material thoroughly before measuring.

2. Dip the viscosity test cup completely into the coating material.

3. Hold the test cup up and measure the time in seconds until the liquid empties out.

Note: This time is called

“Runout Time in Seconds”

.

Viscosity table

Material

Run out Time (Sec)

1) Oil enamel

25-60

2) Oil based primer

30-60

3) Oil stain

No thinning required

4) Clear sealer

No thinning required

5) Polyurethane

No thinning required

6) Varnish

20-60

7) Lacquer sanding sealer

25-35

8) Lacquer

25-35

9) Automotive finishes

20-40

10) Latex

45-90