Summary of Contents for 40 hp

Page 3: ......

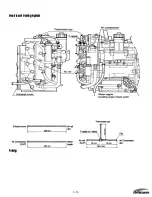

Page 9: ...1 2 2 O 2 O 2 O 2 Outline Dimensions utline Dimensions utline Dimensions utline Dimensions ...

Page 17: ...1 10 ...

Page 19: ...2 2 ...

Page 20: ...2 1 ...

Page 35: ...2 16 5 Special Tools 5 Special Tools 5 Special Tools 5 Special Tools ...

Page 43: ...2 24 ...

Page 48: ...3 5 ...

Page 50: ...3 7 ...

Page 54: ...3 11 ...

Page 57: ...4 2 1 1 1 1 Power Uni Power Uni Power Uni Power Unit t t t ...

Page 60: ...4 5 ...

Page 66: ...4 11 ...

Page 68: ...4 13 ...

Page 72: ...4 17 ...

Page 75: ...4 20 ...

Page 86: ...4 31 ...

Page 97: ...4 42 Piston and Crankshaft Piston and Crankshaft Piston and Crankshaft Piston and Crankshaft ...

Page 106: ...4 51 ...

Page 111: ...5 2 1 1 1 1 Wire Routing Wire Routing Wire Routing Wire Routing ...

Page 112: ...5 3 ...

Page 113: ...5 4 ...

Page 114: ...5 5 ...

Page 115: ...5 6 ...

Page 116: ...5 7 Wiring Diagram 40B 50B EPTO ...

Page 117: ...5 8 ...

Page 118: ...5 9 ...

Page 119: ...5 10 ...

Page 120: ...5 11 ...

Page 121: ...5 12 ...

Page 126: ...5 17 Note Slash shows stripe color of cable 2 2 2 2 Assembly Assembly Assembly Assembly ...

Page 127: ...5 18 Wiring around solenoid Bracket ...

Page 128: ...5 19 ...

Page 129: ...5 20 ...

Page 130: ...5 21 ...

Page 136: ...5 27 Kill Switch Crank Sensor Oil Level Sensor Grounds Air Injector 1 ...

Page 137: ...5 28 Air Injector 2 Air Injector 3 Coil 1 Coil 2 Coil 3 ...

Page 138: ...5 29 Fuel Pump Fuse Box Regulator Stator Complete Wiring harness ...

Page 140: ...6 2 1 1 1 1 Configuration Configuration Configuration Configuration GEARCASE DRIVESHAFT ...

Page 141: ...6 3 GEARCASE PROPELLERSHAFT ...

Page 152: ...6 14 ...

Page 153: ...6 15 ...

Page 185: ...10 20 ...

Page 193: ...11 8 ...