13

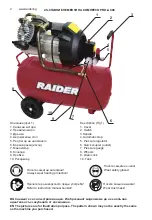

5. MALFUNCTION

Should the machine fail to function correctly,

a number of possible causes and the

appropriate solutions are given below:

AIR LOSS

• May be caused by a poor seal of a connection.

• Check all connections by wetting them with

soap and water.

The compressor runs but does not compress

• May be caused by the valves (C-C2) or a

gasket (B1-B2) being broken.

• Replace the damaged part.

THE COMPRESSOR WILL NOT START

• If the compressor is difficult to start, check:

• whether the voltage of the mains corresponds

to that on the specification plate

• whether electrical extension cables are

being used with a faulty core or length.

• whether the operating environment is too

cold (below 0°C).

• whether there is electricity supply (plug

properly connected, magneto-thermal fuses

not broken).

The compressor does not shut off If the

compressor does not shut off when the

maximum pressure has been reached, the

safety valve of the tank will be activated. It is

necessary to contact the nearest authorised

6. SUPPORT SERVICE FOR THE REPAIR.

Repairs and servicing should only be carried

out by a qualified technician or service firm.

7. CLEANING

Regularly clean the machine housing with a

soft cloth, preferably after each use. Keep the

ventilation slots free from dust and dirt.

If the dirt does not come off use a soft cloth

moistened with soapy water. Never use

solvents such as petrol, alcohol, ammonia

water, etc.

These solvents may damage the plastic parts.

8. LUBRICATION

It is recommended to disassemble the

suction filter every 50 operating hours and

to clean the filter element by blowing it with

compressed air.

It is recommended that the filter element is

replaced at least once a year if the compressor

is working in a clean environment; more often

if the environment in which the compressor

is situated is dusty. The compressor makes

condensed water which collects in the tank.

It is necessary to remove the condensed

water in the tank at least once a week by

opening the drain cock under the tank. Take

care when compressed air is in the bottle

because the water can come out with some

force. Recommended pressure max. 1-2 Bar.

9. DISPOSAL.

The machine, accessories and packaging

should be sorted for environmental-friendly

recycling. The plastic components are

labelled for categorized recycling. Do not

dispose of power tools into household waste!

According the European Guideline 2012/19/EC

for Waste Electrical and Electronic Equipment

and its implementation into national right,

power tools that are no longer usable must

be collected separately and disposed of in an

environmentally correct manner.

Summary of Contents for RD-AC08

Page 53: ...53 ...

Page 54: ...54 www raider bg ...

Page 68: ...68 www raider bg ...

Page 73: ...73 ...