11

tool before making any adjustments, changing

accessories, or storing power tools. Such

preventive safety measures reduce the risk of

starting the power tool accidentally.

1.4.4. Store idle power tools out of the reach

of children and do not allow persons unfamiliar

with the power tool or these instructions to operate

the power tool. Power tools are dangerous in the

hands of untrained users.

1.4.5. Maintain power tools. Check for

misalignment or binding of moving parts, breakage

of parts and any other condition that may affect

the power tool’s operation. If damaged, have the

power tool repaired before use. Many accidents

are caused by poorly maintained power tools.

1.4.6. Keep cutting tools sharp and clean.

Properly maintained cutting tools with sharp

cutting edges are less likely to bind and are

easier to control.

1.4.7. Use the power tool, accessories and

tool bits etc. in accordance with these instructions,

taking into account the working conditions and

the work to be performed. Use of the power tool

for operations different from those intended could

result in a hazardous situation.

2. ADDITIONAL SAFETY MEASURES

Be extremely careful about hidden under

plaster electrical lines, plumbing or gas pipes.

Always check the work area (possibly with a

metal detector).

WARNING! Do not carry MACHINE holding it by

the power cord or GRIP!

OPERATING INSTRUCTIONS

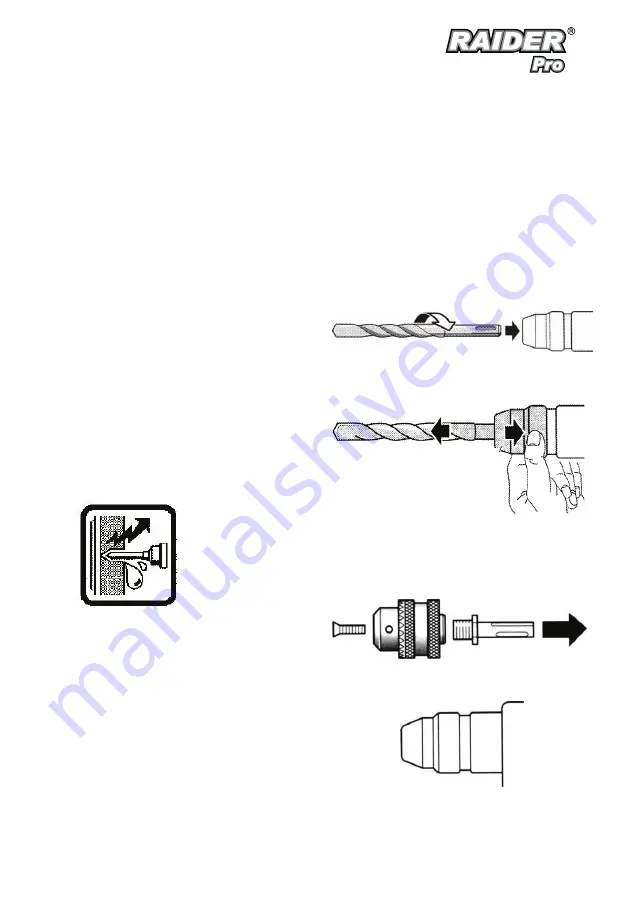

REPLACEMENT of the nozzle.

Attention! Whenever replacing a nozzle check

whether Dust cap is not damaged and is in place,

otherwise contact your dedicated service.

SDS system is designed to grip more easily

and more rapidly changing operating ends of

the machine (chisels, drills, etc.). Drill bits are

automatically centered at work, this does not

affect the accuracy of the breach.

WARNING! NEVER USE OTHER THAN

THE SYSTEM TERMINALS SDS - PLUS FREE

outlined for this purpose chuck (SDS-PLUS

TO CONVENTIONAL)!

3. Attach a working tool.

Carefully clean

the tailpiece of the tool and then grease it (it is

necessary to reduce friction during operation)

.Remove the chuck release mechanism. Place

the tool in the chuck hole and rotate it gently until

the drill “sinks” smoothly into the grip. The tool is

locked automatically after returning the release

mechanism to the starting position.

4. Removing a tool.

Pull the release mechanism back and hold in this

position while removing the tool.

5. Working with conventional work tools.

For the use of tools other than the SDS-Plus

system, the use of a conventional chuck (not

supplied) fitted to a dedicated spindle (adapted

for SDS grip) is required.

6. Install the chuck to the grip.

The fitting of the chuck is analogous to item

3 “placing a working tool”.

7. Installing a tool in the conventional chuck

(pre-installed !!!).

Fix the chuck ring securely and loosen the front

Summary of Contents for RDP-HD05S

Page 76: ...76 www raider bg Exploded drawing of Rotary Hammer RDP HD05S ...

Page 77: ...77 Parts List Rotary Hammer RDP HD05S ...

Page 87: ...87 ...

Page 92: ...92 www raider bg ...