5. After repeating the procedure for the other motor, reassemble the chassis and

body, being careful that the wire harnesses are not caught between the chassis and

body, and reinstall the body mount screws.

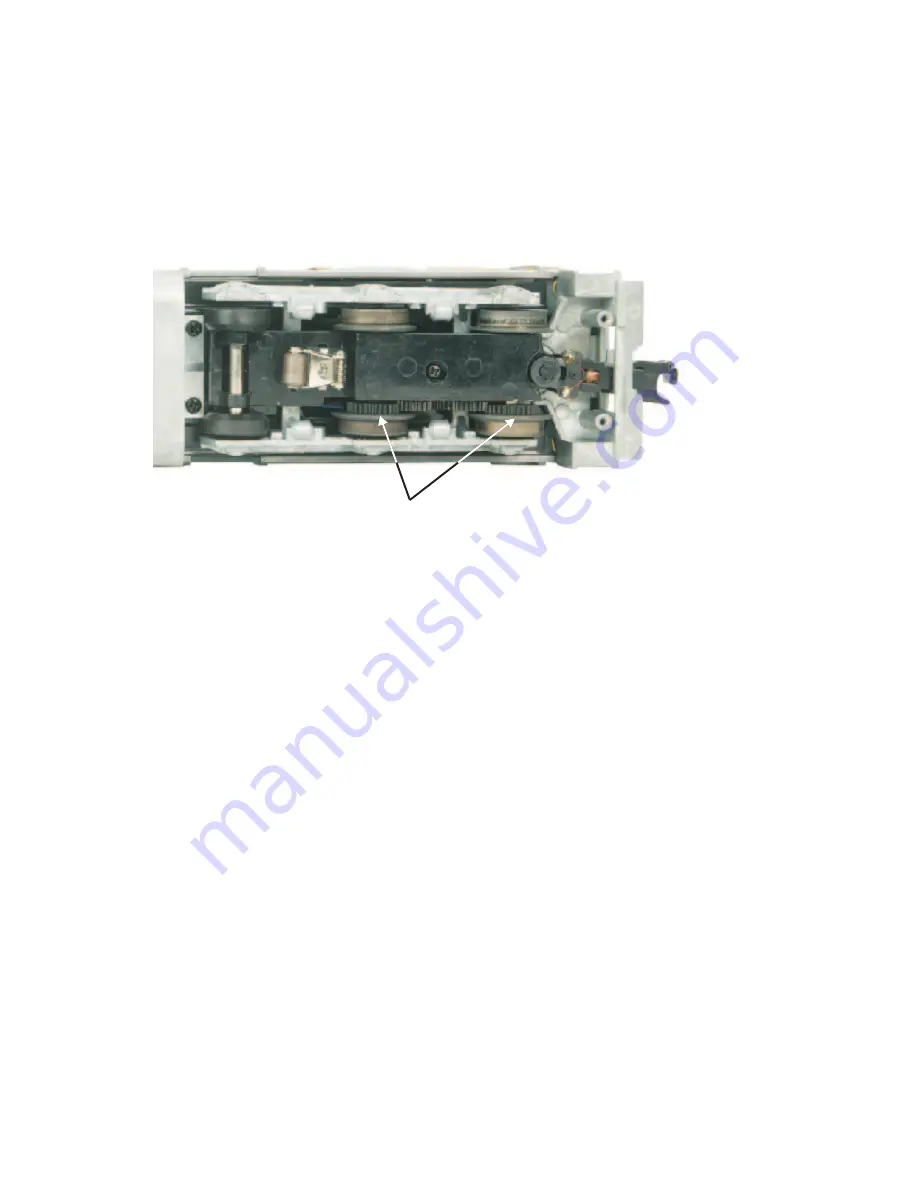

Lubricate the outside truck block idler and drive gears with grease. Use the

diagram shown in Figure 6 below as a guide and add grease to the points marked.

Cleaning The Wheels, Tires, and Track

Periodically check the locomotive wheels and pickups for dirt and buildup, which

can cause poor electrical contact and traction and prematurely wear out the

neoprene traction tires. Wheels and tires can be cleaned using denatured (not

rubbing) alcohol applied with a cotton swab.

To clean the track, use RailKing Track Cleaning Fluid or denatured (not rubbing)

alcohol and a clean rag. Unplug the transformer and wipe the rails of the track,

turning the rag frequently to ensure that you are using clean cloth on the rails.

Thereafter, keep an eye on the track and clean it when it gets dirty to ensure good

electrical contact and to lengthen the life of the tires.

RKS SD-45 Diesel Engine with

10

Loco-Sound

Figure 6. Greasing The Idler Gears

Grease Idler Gear (G)