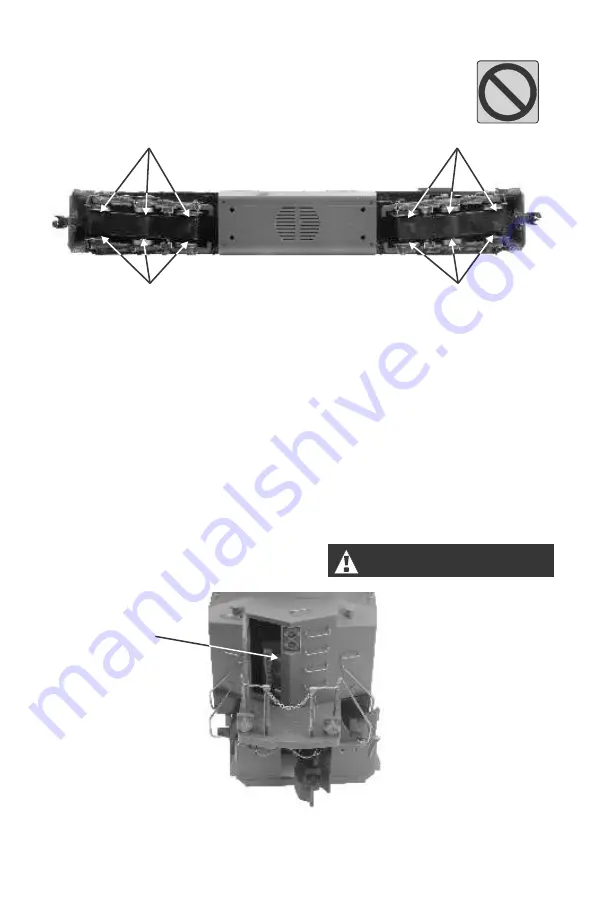

Lubrication

You should lubricate the engine to prevent it from squeaking. Use light

household oil and follow the lubrication points marked “L” (shown

below). Do not over-oil. Use only a drop or two on each pivot point.

Priming The Smoke Unit

When preparing to run this engine, add 30-40 drops of smoke fluid through the

smokestack. We recommend M.T.H. ProtoSmoke™ fluid. Do not overfill the unit or

the fluid may leak out and coat the interior engine components.

If you choose not to add the fluid (or have already added the fluid but choose to run

smoke-free), rotate the smoke unit control located inside the cab front door (shown

below) to the off position (rotate counterclockwise). If you wish to regulate the smoke

output intensity, turn between full counterclockwise and full clockwise until the desired

smoke output is reached. Failure either to add fluid to the unit or to turn it off may

damage the smoke unit heating element and/or wicking material.

Figure: Smoke Unit Switch Location

Running the engine without a primed

smoke unit may cause damage

DO NOT

OVER OIL

DO NOT

OVER OIL

RailKing One-Gauge SD70ACe Diesel Engine w/Proto-Sound® 3.0

Smoke Unit Control

Figure: Lubrication Points on the Locomotive

8

Lubricate All Wheel Axles (L)

Lubricate All Wheel Axles (L)

Lubricate All Wheel Axles (L)

Lubricate All Wheel Axles (L)