ENGLISH

PIKUS 105/105DL – PIKUS 75/75DL

17

POS. CODE

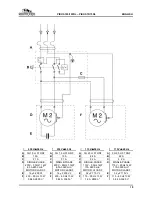

PART

NAME

1

423BL75

423BL105

TILE HOLDER DEVICE (PIKUS 75)

TILE HOLDER DEVICE (PIKUS 105)

1\1

423AST75

423AST105

CLAMPING ROD (PIKUS 75)

CLAMPING ROD (PIKUS 105)

1\2

423PBLPS

TILE HOLDER DEVICE SUPPORT

1\3

423PBLPL

TILE HOLDER DEVICE SUPPORT

1\4 423MANSNO CONNECTING

ROD

FOR

ARTICULATION

1\5 306MA01D HANDKNOB

1\6 310BS07D BUSHING,

O.D.19

1\7

314TO04D

TORS. SPRING F2.5

1\8 322QU01C PLUG,

20X20

1\9 354CAT022

RUBBER STRIP LL570 (PIKUS 75)

RUBBER STRIP LL870 (PIKUS 105)

2 154SE05D MOTOR

TRANSPORT

HANDLE

3

192SQ01A

COMPLETE TRIANGULAR SQUARE

3\1 305MR06C HANDLE

3\2 191TL03D TRIANGULAR

SQUARE

3\3 191PE01D SQUARE

HOLDER

SLIDER

4

235ZS01A

235ZS02A

STARTER 230V 50/60HZ

STARTER 110V 50/60HZ

4\1

234MD01C

234MD02C

234MD04C

MICRO CIRCUIT BREAKER 16A 230V 50/60HZ

MICRO CIRCUIT BREAKER 16A 110V 50HZ

MICRO CIRCUIT BREAKER 16A 110V 60HZ

4\2

234TR04C

THERMAL SWITCH, 211 15A 230V 50/60HZ

4\3

246PM03D

MICRO CIRCUIT BREAKER HOLDER, 2 PCS

5

240

240110

IMM. PUMP 230V.50/60HZ

IMM. PUMP 110V.50/60HZ

6 263PE01A SPRAY

GUARD

7 264PV04C MOBILE

SOCKET

8 268MC01D MOTOR

BLOCK

9

297IN25D

297IN26D

INDUCTION MOTOR 1.1kW 230V 50/60HZ

INDUCTION MOTOR 1.1kW 110V 50/60HZ

9\1 303VM06C FAN

9\2 2872501C CAPACITOR

9\3 3047101C FAN

COVER

10 309CS01A SHEAVE

WITH

BEARINGS

11

311RB03D

LEG WITHOUT WHEEL HOLDER

12

311RB02D

LEG WITH WHEEL HOLDER

13

325VP10D

325VP15D

TANK FRAME (PIKUS 75)

TANK FRAME (PIKUS 105)

14 320PG03C SHEATH

TERMINAL

15 156BS02A LH

FENCE

15\1 423LEVAA LEVER

(A)

15\2 423CERSX LH

HINGE

15\3 156RB02D LH

SWINGING

GRID

15\4 423LEVAB LEVER

(B)

16 156BS02D RH

FENCE

16\1 423LEVAA LEVER

(A)

16\2 423CERDX RH

HINGE

16\3 156RB01D

RH SWINGING GRID

16\4 423LEVAB LEVER

(B)

17 423AS+RON LOCKING

PIN

18

263FE07D

MOBILE DISK GUARD

19

114RE09D

114RE10D

GUIDE (PIKUS 75)

GUIDE (PIKUS 105)

20

156NL09D

156NL10D

AL. GRID (PIKUS 75)

AL. GRID (PIKUS 105)

21

158GB02D

RING NUT, Ø75

POS.

CODE PART

NAME

22 179CC250Q DIAMOND DISK, Ø250 F25.4 SMOOTH CROWN

23 191GE02D GUIDE FOR SQUARE, LL450mm

24 191AE04D

SQUARE FOR SUPPORT, LL216mm

25 251RE05D ALUMINIUM

COLUMN

26 262PO02D DISK COVER, COVER Ø200 Ø250

27 262CO05D DISK COVER, DOOR Ø200/250

28 265LM01D CASING ON MOTOR SIDE

29 265LD01D CASING ON DISK SIDE

30 278PA01D DISK

HOLDER

FLANGE

31 278PB01D

DISK FIXING FLANGE

32 286PV02C POLY-V

BELT

33 292VA06D PULLEY,

Ø48

34 292VA05D PULLEY,

Ø34

35 293PM02D MOTOR

SUPPORT

36 294PC03D SHEAVE

HOLDER

37 305PF06

FEM. KNOB, Ø40 8MA

38 305PF15C

FEM. KNOB, Ø60 8MA

39 305MR06C HANDLE,

8MAX25

40 305PM35C MALE KNOB, Ø60 10MAX40

41 305PF12C

FEM. KNOB, Ø40 6MA

42 306MA01D HANDKNOB

43 3081503C

BEARING, 6202 ZZ

44 310BS12D BUSHING,

O.D.14

45 310BE01D BUSHING,

CH17

46 314AN02D CABLE-CARRYING

SPRING

47 314TO02D TORS. SPRING, ØF3.8

48 314TO03D TORS. SPRING, ØF2.5

49 315CB10C WHEEL,

Ø125

50 320PA02C CORE

HITCH

Ø50

51 322CN03C TAPERED

PLUG

52 322QU01C PLUG,

20X20

53 322RE04C PLUG,

60X20

54 324RU01C TAP

55 324DE01C DEVIATOR

56 903TERRA EARTH

LABEL

57 218PPOMPA PUMP

HOLDER

58 423ASTRIN DISK COVER TRANSMISSION ROD

59 423PASOLA PLATE

WITH

SLOTS

60 900CH6X15 TAB,

6X6X15

61 423ALBPDS DISK

HOLDER

SHAFT

62 900RORA10 SHIM, Ø105

63 900RORA56 SHIM, Ø56

64 900ANCO55 COMPENSATION RING, Ø54.8

65 423OR

SEAL, 22 X 32 X 7

66 423REGSQU SQUARE

ADJUSTER

67 420LETTOR DEGREE

INDICATOR/SQUARE

68 420MM

SCALED ADHESIVE LABEL FOR SQUARE

69 903PIKUS NAMEPLATE

70 423PRUBIN TAP SUPPORT PLATE

71 192SQ03A COMPLETE FIXED SQUARE ASSEMBLY

71\1 191PE01D SQUARE

HOLDER,

LL55mm

71\2 305MR06C HANDLE

71\3 191SF05D FIXED

SQUARE

72 323BR03C SETSCREW,

SIZE

5

73 323CH12C WRENCH,

SIZE

22

74 288

WHITE

SHARPENING

STONE

75 158GB03D SELF-LOCKING RING

76 374MM

SCALED ROD, LL520mm

Summary of Contents for PIKUS 105

Page 1: ...GB...

Page 2: ......

Page 16: ...PIKUS 105 105DL PIKUS 75 75DL ENGLISH 16...

Page 19: ......