PIKUS 105/105DL – PIKUS 75/75DL

ENGLISH

8

Assembling/Disassembling the machine

BEFORE PERFORMING ANY OPERATION, MAKE SURE THAT THE MACHINE IS

UNPLUGGED.

TWO PERSONS ARE NEEDED TO ASSEMBLE THE MACHINE

Assembly:

•

Take the machine off the pallet and check for

broken or damaged parts.

•

Unscrew the two knobs (A) from the rear feet,

namely the feet featuring wheels;

•

Whilst one operator raises the rear side of the

machine, the other should pull down the feet and

fasten them with the knobs provided for this

purpose (A);

•

Repeat the above steps for the front side of the

machine.

Disassembly:

•

Repeat the above operations in reverse order

(first the front section, then the rear).

Water supply

Pour clean water into the machine’s tank until the pump is entirely immersed in the cooling

circuit.

Regulating cut depth

BEFORE PERFORMING ANY OPERATION, MAKE SURE THAT THE MACHINE IS

UNPLUGGED.

The PIKUS machine can be used as follows:

•

With the motor assembly locked in place at the

desired cutting depth, tightening the handle (D).

•

Manually lowering the motor assembly using grip

(E) (knob (D) loosened).

When performing cuts on material longer than 90 cm

for the 105/105DL version and 60 cm for the

75/75DL version, proceed as follows:

•

Release the motor assembly by slackening the

knob (D), so that the disk is in its top-most

position, then move it to its rear stroke end.

•

Position the piece to be cut on the table.

•

Press the start button and wait until the cooling

water reaches the disk.

•

Using the grip, slowly lower the motor assembly

so that the disk enters the material. Lock the

motor assembly in place by tightening the knob

(D)

•

The machine is now ready to cut (see Cutting).

ATTENTION: WHEN MAKING PARTICULARLY THICK CUTS, IT IS BEST TO PASS OVER THE

MATERIAL AS MANY TIMES AS REQUESTED BY ITS HARDNESS.

F

IG

.

5

F

IG

.

6

E

D

A

A

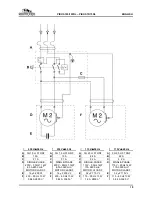

Summary of Contents for PIKUS 105

Page 1: ...GB...

Page 2: ......

Page 16: ...PIKUS 105 105DL PIKUS 75 75DL ENGLISH 16...

Page 19: ......