2

3

)

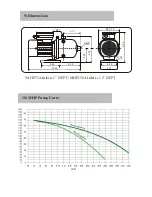

Installation Illustrations:

F) Air is entering the pump through the suction side: the pressure is well below normal, with

constant fluctuations. The safety system will engage and stop the pump, the

FAILURE LED will

light up. Check the seal and connections in the suction pipe.

3

THE PUMP KEEPS STARTING AND STOPPING:

There is a small leak in the delivery pipeline: check for any leaking taps or running toilets.

Summary of Contents for MHP75A

Page 12: ...MHP75A MHP150A Pump...